3D metal printing with process monitoring

18 December 2021

At the recent Formnext 2021 exhibition, the CHIRON Group demonstrated its interpretation of the event's slogan, ‘The next generation of intelligent industrial production’. For the first time, the team from the Additive Manufacturing department presented the AM Cube in person. The innovative 3D metal printer for laser deposition welding has already proven a hit at a CHIRON online Open House and it has gained significant interest in the UK from customers of the Engineering Technology Group (ETG), the UK’s technical partner to CHIRON. The event also delivered the opportunity to see two new features – the comprehensive documentation of process data with DataLine AM and the ability to record the welding process in real-time with VisioLine AM.

Even more possibilities for additive manufacturing

Laser deposition welding with AM Cube is suited to a whole variety of different processes and industries, including mechanical engineering, tool manufacturing, energy production and the aerospace industry. From coating components to making repairs to near-net-shape production of semi-finished products, there are so many applications for additive manufacturing. What's more, the AM Cube enables even more possibilities. The CHIRON Group has succeeded in offering two processes – laser deposition welding with both wire and powder – from just one comprehensive system. A real advantage of the AM Cube is that the deposition head is changed fully automatically during the process, with the system offering up to three deposition heads.

The 3D metal printer is a future-proof combined solution for additive manufacturing and has been designed using a Cartesian coordinate system, just like a conventional machining centre. The laser deposition welding technology is especially well-suited to small quantities and large components with long procurement times and high material prices. This is particularly thanks to the AM Cube’s effortless switching from four to 5-axis machining, achieving high order volumes while maintaining excellent surface quality. In addition, the comprehensive safety and protective equipment enables unmanned operation.

Process monitoring with DataLine AM and VisioLine AM

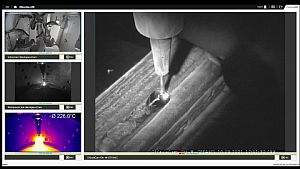

To analyse and optimise the process of laser deposition welding in a targeted way, two new digital systems are available for the AM Cube. Firstly, DataLine AM means that all relevant process data can be displayed, recorded and documented continuously in real-time. This allows product and process quality to be assessed with certainty. Secondly, VisioLine AM visualises and saves video files recorded by multiple camera systems (e.g. the melt pool camera, thermal camera, workpiece camera, working area camera), thereby enabling systematic process monitoring.

Moreover, at Formnext, the team from the Additive Manufacturing department demonstrated the perfect interaction of additive manufacturing and machining. They also presented a preview of a second innovation project, AM Coating. This is a system designed for applying particularly hard coatings on brake disks and rotationally symmetrical components. If you missed the Formnext show and would like more information, please contact the Engineering Technology Group (ETG).