ACT Extends Part-off & Grooving Range

20 March 2013

The renowned series of MicroCut small turning and parting tools from Advanced Carbide Tooling (ACT) has now been extended to incorporate new insert grades. With its new grades, the MicroCut product range of parting and grooving tools for the manufacture of small components is the perfect complement to the company's existing range of highly productive ACT 2.2 turning, parting and grooving tools.

The new MicroCut inserts are available from widths of 0.5 to 1.6mm with new carbide TiALN coated and HSS/TiN coated inserts. These insert dimensions perfectly suit ISO standard circlip grooves. The new TiAlN coated insert grade has been added to a super fine micro grain carbide composition that gives the inserts an extremely sharp edge that is resistant to chipping to guarantee exceptional tool life and surface finishes. This new grade incorporates XCEED coating technology that ensures tool life and productivity rates are extended beyond that of competitor grades.

Also added to the UK manufactured range is the new HSS TiN insert grade for machining small diameters. The new HSS TiN coated grade provides the ideal combination of a tough substrate with an extremely sharp cutting edge. This is well suited to the turning and parting of small parts with intricate features that demand the utmost in precision, repeatability and above all consistent tool life.

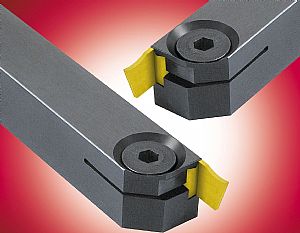

The maximum insert reach is 8mm to allow end users to part off up to 16mm solid bar, whilst retaining the strength, rigidity and tool life that is expected from ACT's high quality range of parting and grooving tools. With a selection of approach angles to meet the individual needs of the end user, the new MicroCut grades can be held in toolholders with dimensions down to 8X8mm for particularly small tool platens. This extends up to 20x20 shanks for larger parting off and grooving applications. The toolholders have a rigid design that further enhances tool life whilst providing the end user with quick change system for minimum downtime.

Ideal for machining a diverse range of materials from steel, carbon steels, alloy steels and stainless steels through to copper, bronze, brass, aluminium alloys, titanium's and high chrome and nickel content materials, the performance of the new MicroCut grades have delighted the marketplace. Tested against established grade designations from leading competitors, the MicroCut has been proven to extend tool life, improve surface finishes and be more consistent on sliding head turning centres in a production environment.