ACT Gets into Groove with New Indexable Engraving Tools

14 December 2012

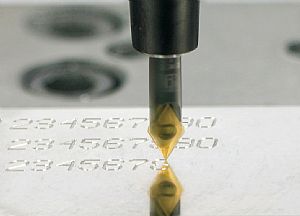

For manufacturers demanding high quality and high definition marking and engraving, Advanced Carbide Tooling (ACT) has now developed its new range of engraving tools. Utilising indexable carbide inserts with a corner radius as small as 0.1mm, the ACT engraving range is a cost efficient and time saving alternative to solid carbide engraving tools.

The new ACT innovation is suitable for engraving a wide variety of materials from aluminium, plastics and non-ferrous materials through to carbon, stainless and hardened steels and cast irons. This diversity is credit to four insert geometries that are available with a TiN or TiAlN coating for improved tool life. As an addition to ACT's Nine 9 series, the universal marking tools are suitable for engraving any character or number that can be created by an NC program. With a choice of 45 or 60 degree insert angle, the new series can be used for marking serial numbers, product codes, dial scales, signs, logos and any other character imaginable.

From a productivity standpoint, the ACT engraving tools have a multitude of benefits over traditional solid carbide or HSS engraving tools. For example, when wear occurs on carbide or HSS tools the operator has to change the tool or furthermore, regrind the tool and then re-set the tool parameters. With the new ACT engraving tool, the operator can efficiently remove the insert and index to the next edge without any concern over re-setting the machine tool. With two cutting edges per insert, the ACT tools ensure the tool length is unchanged between insert changes, thus offering unparalleled repeatability and accuracy for the customer.

Furthering the accuracy of this engraving series is a geometry design that is fully ground on the periphery to ensure repeatability whilst guaranteeing burrs are a thing of the past. With a high positive rake angle, the engraving tools are capable of running at speeds up to 20,000rpm and feed rates of 0.08mm/rev. This exceptionally high speed and feed rate ensures the Nine 9 engraving series can mark components at speed and feed parameters far beyond competitor products whilst guaranteeing a high quality, burr free surface finish.

Available with a 0.1 or 0.2mm corner radius, the 2mm thick inserts incorporate a 6mm long cutting face for engraving at increased depths. The inserts are complemented by rigid and robust toolholders that eliminate vibration and improve surface finishes at high speeds and feeds. The round shank toolholders are available in 6mm diameter with lengths of 40, 60 and 100mm for extended reach applications. The toolholders are also available with the option of steel shank or solid carbide shank to further enhance the rigidity.