ACT Hits The Spot At EMO 2013

14 June 2013

At Europe's showcase manufacturing event, leading Japanese cutting tool manufacturer Nine9, will be launching a number of new innovations. The EMO event taking place in Hanover in September will note the Nine9 range extended with the launch of the new I-Center indexable centre drill and the W-Spotting tool for spotting and chamfering tapped holes. Available in the UK through Hinkley based Advanced Carbide Tooling (ACT), the new products are already creating excitement among UK customers.

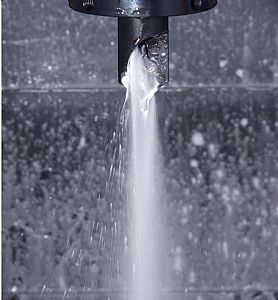

The new I-Center is the world's first indexable centre drill that is capable of increasing tool life and process performance whilst eliminating re-sharpening and re-setting, resulting in improved cycle times and reduced downtime. With insert positional accuracy nailed to 0.05mm, tool length setting and repeatability is unparalleled. The I-Center toolholder is available in numerous lengths and diameter options to offer insert cutting widths for holes from 8 to 25mm diameters.

Furthermore, to ensure the new I-Center is capable of meeting the diverse needs of the marketplace, the K20F grade carbide inserts are available with TiAlN coatings for the machining of carbon and alloy steel, high alloy steel, cast iron, aluminium and aluminium alloys. Offered in DIN and ANSI dimensions, the new I-Center will certainly be a crowd pleaser at EMO.

Also making an EMO debut alongside the I-Center will be the new Nine9 'W' spotting tool for spot drilling and chamfering holes in one operation. Eliminating the need for a spot drill and chamfer tool, the new 'W' spotting tool shortens cycle times, improves accuracy, hole position and consistency whilst reducing the customers' tooling inventory. By replacing two processes with one, the 'W' Spotting tool from Nine9 delivers a realm of cost reduction and cycle time saving possibilities for the end user.

The 'W' Spotting tool is available with two toolholder diameters of 10 and 16mm with a respective shank length of 89 and 97.5mm. Suitable for metric threads from M4 to M10 and imperial threads from 1/4 to 3/8UNC, the K20 grade carbide inserts with TiAlN coating has been created as a universal grade for steel and cast iron machining.

Both the new developments from Nine9 will appear alongside the company's established corner rounding cutting tools. Whilst already a formidable product in the marketplace, Nine9 has now extended the corner rounding range to provide corner rounding inserts from 0.5 to 1mm in 0.01mm increments. This product extension that will be launched at EMO will target the micro machining sector whilst bolstering the existing corner rounding range that is available from 1 to 6mm. The exceptional new corner rounding addition supports the 'flexibility' philosophy that Nine9 is renowned for, by enabling the corner rounding toolholders to also accept the Nine9 series of chamfering inserts. Thus reducing tool inventory and changeovers even further for the end user.

As well as showcasing these new developments at EMO, Nine9 will also be demonstrating an extensive selection of its established and market leading cutting tool technologies. For further details on the innovation possibilities from Nine9 and ACT, please visit Hall 5 Stand D70 at EMO or contact your local ACT office.