ACT / Nine-9 Helix Drill - One Tool Does It All..

15 July 2015

With tool changeovers and reduced 'chip to chip' time being buzzwords among highly productive machine shops, Advanced Carbide Tooling (ACT) has now introduced its exciting new NC Helix Drill from Nine9 to eradicate 'non-cutting' times.

This truly multi-functional new tool is capable of helical interpolation milling, ramping, slotting, counter-boring and drilling with a single tool. Taking flexibility to a whole new plateau, the NC Helix Drill only requires six different tools for drilling precision holes from 13 to 65mm diameters. Furthermore, the drill is supplied with just one insert grade that can machine a wide variety of material types.

Working on an interpolation cycle, the NC Helix Drill reduces the cutting load on the spindle by ramping at an angle up to 20 degrees whilst the serrated insert edges break the swarf into fine chips that are easily evacuated from the hole.

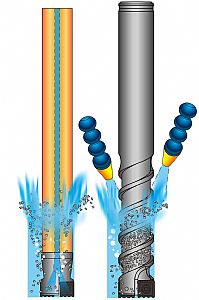

Meanwhile the drill body is available with either a cylindrical shank or as a screw fit holder that can fit most toolholder extension bars on the market. The cylindrical shank toolholder has been developed for machines without a through coolant facility whereby a helical groove on the shank evacuates swarf whilst rotating. The screw-fit option delivers uncompromising flexibility and its through coolant facility permits the rapid evacuation of chips from the cutting area.

The impressive new insert design has two cutting edges per insert with a geometry that provides a serrated cutting edge on the two edges. Manufactured from a K20F micro grain carbide substrate that is TiAlN coated; the combination of grade and geometry provide remarkable tool life on all types of material from aluminium, carbon steel, low and high alloy steel, stainless steel, cast iron, nickel and titanium alloys. The inserts are available in five dimensions to suit the corresponding drill bodies and also to maximise material removal rates for the end user.

As for the innovative drill body of the patent pending series, the cylindrical shank tool body is manufactured from a hardened high alloy steel to extend tool life and rigidity. The helical groove has been optimised to rapidly remove swarf and coolant from the cutting zone. Available with shank diameters of 10, 12, 16, 20 and 25mm, these drill bodies can achieve a drilling diameter range of 13 to 20mm, 15 to 25mm, 20 to 30mm, 25 to 40mm, 30 to 50mm and 42 to 65mm. To improve performance, Nine9 has developed the cylindrical shank tool with an overall length from 80 to 220mm with a length of cut from 40 to 100mm.

For end users that desire through coolant drills, Nine9 offers the screw fit heads with a cutting diameter of 11, 13, 17, 22 and 27mm that will interpolate to meet the exact diameter demands of the end user. These inter-changeable heads can be inserted into steel or solid carbide extension bars. The steel extension bars are available in diameters of 12, 16, 20 and 25mm with an overall length of 75, 90, 100 and 120mm respectively. For customers that are aiming to drill particularly deep holes, ACT suggests the TiN coated carbide shank that enhances rigidity and the consequent surface finishes when using the available shank lengths of 100, 150 and 200mm.