Bottling Successful Precision With Blum

With the worldwide consumption of PET bottle caps estimated at 4 billion pieces a day, it is obvious that the production of plastic caps for the beverage, cosmetic or household industries is a lucrative field. This lucrative industry has its relentless rules and regulations.

The Czech producer of base plates for multiple injection moulds, the Tirad company, has been a part of the supply chain, at the end where the most significant players like Coca Cola or Pepsi have figured for several years. To be such an integral part of this supply chain, Tirad has implemented measuring systems from Blum-Novotest.

Stanislav Veselý, the Executive Director of Tirad comments: “There are incredible volumes. For instance, a 96-multiple mould having the frequency of 3.5 seconds is able to produce 26 tonnes (approximately 1 truck) of PET caps a day. When you produce such amounts, even a small reduction in plastic consumption in the order of 3–5% poses significant financial savings. Therefore the pressure on the price of the product has created a very specific demand to combine as many cavities as possible in a mould with the closest tolerance. The positional accuracy of cavities affects the wall thickness of the cap and also the financially monitored plastic consumption.“

While the tolerance of cavity positioning was formerly ±0.01mm/m, the Tirad company has carried out orders for customers that have a working tolerance of ±0.005 mm/m. “We had to adapt to the market with regard to precision and also to the size of frames that are made up to dimensions of 1500 x 2500mm. When you realize that our coordinate measuring machine determines the position and achieves an accuracy of 0.004mm/m, we are, in fact, approaching a tolerance band more akin to a laboratory than a production facility,“ Mr Veselý points out.

Absolute technological discipline

The production at Tirad really has the character of working under laboratory conditions. Considerable investments were directed especially towards the thermal and technological stability of the manufacturing process and towards the reduction of human errors. Manufacturing technology in air-conditioned space is actually subject to strict in-house regulations. A minor deviation, in form of a tool set-up to an incorrect length against the verified length, may cause vibration in the cut and this may exceed the micron tolerance.

This is also confirmed by Mr Veselý: “In respect of the tool and workpiece set-up, we needed to gain much firmer ground, and that‘s why we began thinking about the implementation of measuring probes in our production process.”

Blum – a guarantee in quality

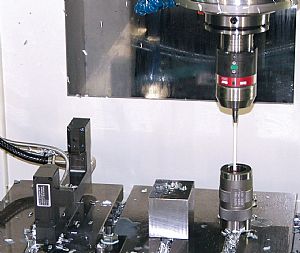

The principal role in the choice of laser and touch probes was played by maximum accuracy and long-term process reliability in the machining area. As Mr Veselý adds: “If you take hundreds of measurements of a micron tolerance a day in a three-shift operation, the circle of potential suppliers is already very narrow. We knew the Blum company as a supplier of first-class laser systems, but also the measuring probes of the TC line persuaded us of their qualities during tests lasting several months. Following trials, we have 5 machines fitted with the Micro Compact NT laser and with the TC50 touch probe. Owing to our marvellous experience, in time we intend to acquire some more.“

TC50 – touch probe for universal applications

The TC50 probe is designed for universal applications in machine tools, particularly in those with limited accuracy demands at high dynamic and measuring speeds of up to 3m/min. Robust symmetrical design, non-contact signal generation and higher measuring force are attributes that guarantee exceptional measurement repeatability independently of speed, stylus length or pollution of the measured surface.

Using the TC50 touch probe, Tirad automatically determines the zero point and monitors the flatness of the base plate in 7 points having a tolerance of 0.005mm. This is a demanding application that takes full advantage of the progressive measuring mechanism inside of the probe. In the course of measuring, a text file is generated that stores measured values and can be used for a possible reverse analysis.

Micro Compact NT

Each cutting tool is measured first by the Micro Compact NT laser system whereby measurements are taken using a focused laser beam of 0.03mm in diameter. This calibration takes place under identical conditions as machining. In this way, it is possible to get results approaching the absolute reality – unlike an external measuring device.

The measured length offset compensates inaccuracies resulting from tool change clamping errors or from temperature and dynamic changes in the spindle and the machine. The automatic data transfer into a tool offset table eliminates any human error and the tool data is retrospectively available in a text file. Blum with its 25 years of know-how in laser measuring systems is the world leader in this industry. The ingenious combination of optics, micro-electronics, mechanics and software, guarantees excellent measurement repeatability and almost maintenance-free operation in the long term.

Unproductive time has disappeared

Everyday life of any supplier revolves around these words: price, delivery time and quality. It is then quite logical that companies wanting to get to the top or to remain there are looking for ways to manufacture faster, more precisely or more efficiently.

Tirad found the way to master its production and to lay down rules for it. Although it is purely a piece production, the overwhelming majority of the machining process works without any operator intervention just by touching the green button of ‘cycle start’.

“The Blum probes have become the standard for us. They present not only current geometric accuracy to us, but they also present retrospective views by storing valuable data for the later analysis of finished machining. However, they are also a glimpse into the future, because lots of unpredictable unproductive time has disappeared thus making price calculations of the demanded work much more specific,” Mr Veselý concludes.