Floyd Enters High Feed Milling Market

7 February 2014

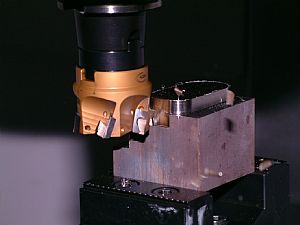

To complement its extensive selection of cutting tools for the machining of turned parts, Floyd Automatic is now introducing a new line of milling tools. The Alesa milling line from Floyd Automatic is available with end mill and face mill options that have been developed specifically for high speed and high feed milling processes.

The new AO10, AO15 and AP16 end mills are available with diameters from 16 to 40mm and this is extended by the AO10, AO15, AO20 and AP16 range of face mills with diameter options ranging from 32 to 160mm. The AO10 range of milling cutters is available as an end mil or screw-on type cutter with diameters including 16, 20, 25 and 32mm with 2, 3, 4 or 5 insert pockets. For higher removal rates, the AO10 face mill is available in diameters of 32, 40 and 50mm with 5, 6 and 8 insert seats respectively.

For larger diameters and higher volume material removal, the Alesa AO15 end mills are offered in diameters of 25, 32 and 40mm with face mills for 40, 50, 63 and 80mm diameters. This combination is offered with anything from 2 to 9 insert pockets depending upon cutter diameter.

The combination of end mills and face mills with through coolant facility enable the Alesa milling range to conduct profile milling, slotting, face milling and circular interpolation machining with exceptional material removal rates. The R&D team at Alesa has worked tirelessly to develop its series of HSS-E, HSS-E Chip Splitting, Alesa X2, Carbide HM and Carbide HM-F insert designations. This extensive range of innovative inserts offer a host of different geometries that are either TiN, TiAlN, AlCrN or AlCrN-VA coated. Furthermore, HSS & carbide inserts are available with a multitude of radii and geometries that can be PVD coated. What this delivers for the end user is a range of cutting tools and corresponding insert grades for machining anything from plastics, brass and copper through to steel, stainless steel, cast irons and aluminium alloys such as titanium, inconel, super duplex and additionally difficult to machine materials.

The Alesa range of milling cutters are available with two insert sizes, SD09 and SD12 that offer machining depths up to 1.5mm and 2.5mm respectively. The exciting geometries of the Alesa milling line permit efficient machining performance with high material removal rates on all types of machine tool. The efficient cutting geometries deliver rigid and robust machining of difficult materials, even on low powered machine tools.

By minimising the cutting forces, low spindle powered machines can deliver exceptional material removal rates whilst minimising vibration and associated noise levels whilst improving surface finishes. For more robust machine tools, the Alesa range has proven to outperform competitor products in trials on stainless, super duplex and cast iron with regards to speeds and feeds - resulting in drastically improved cycle times.