Floyd Focus on OEM Open House Events

16 September 2013

With the plethora of new product launches at EMO in September, the UK's manufacturers of sliding head turning centres will all be hosting Open House events this Autumn. With the Citizen/Miyano event on the 8th to the 10th of October(www.citizenmachinery.co.uk), the Tornos Technology Event from 15 to 17th October (www.tornos.com) and the Star Micronics Open House (www.stargb.com), the UK's turned parts fraternity will have a wealth of new products and innovations to investigate. Supporting all these manufacturers at the three events will be Floyd Automatic Tooling with its cutting tools, collets, guide bushes and tool holding innovations.

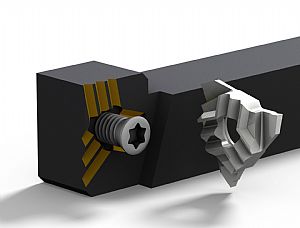

Regarded as the specialist supplier of solutions for the turned parts market, Floyd Automatic will be demonstrating a number of new innovations that will be fresh from EMO alongside some established and highly successful product ranges. From a cutting tool perspective, the established and highly productive new TRIO-Line of turning tools from Applitec will be of interest. With the new TRIO-Line, the Swiss tooling specialist has created a cost effective range of inserts for precision grooving and fine turning that deliver exceptional rigidity for outstanding performance.

Applitec has developed its unique insert using their classic ‘ridge’ clamping technique with three teeth on the surface that lock the insert into position with the ridged toolholder. This clamping process drastically improves clamping strength with three protrusions on the toolholder mating perfectly with the insert. Beside enhancing rigidity for productivity and surface finish enhancements, the design offers three cutting edges on a triangular insert for improved cost and productivity per insert.

Also on show from at the events from the Applitec stable will be the innovative TOP-Line 700-JET turning toolholders to accommodate high pressure coolant. The new coolant fed toolholder for the TOP-line turning range delivers coolant directly to the cutting edge to improve tool life, productivity and surface finishes credit to its remarkable ability to clear swarf. The 700-JET series is available in left and right hand toolholders for both 730/740 series and the 750/760 series inserts.

Delivering productivity improvements to sliding head turning centre users, Floyd will also be showing the new Mowidec-TT spindle centring system. The new Mowidec-TT is a spindle centring system that enables the user to perfectly centre tools on the main or counter spindles to improve accuracy, performance and tool life with a simple and fast method on Swiss automatic lathes. When changing the set-up or settings on an automatic lathe, operators frequently have to re-centre the spindles, usually with a dial test indicator. Whilst this can be conducted in a number of ways, the process is so restrictive that operators often prefer not to do it at all - resulting in poor quality, precision and premature tool wear.

With the Mowidec-TT, centring is carried out without removing either the guide bush or the tools. It is conducted without any complicated equipment or training and is so simple that users start centring systematically, thereby benefitting from enhanced tool life and productivity.

To learn what new innovations will be available to reduce your set-up times whilst enhancing your productivity, quality and profitability, please visit our stand at any of the three Open House Events.