Floyd Gets into Groove With New TRIO-Line

25 January 2013

Floyd Automatic Tooling has now launched the new TRIO-Line of turning tools from Applitec. With the new TRIO-Line, the Swiss tooling specialist has created a cost effective range of inserts for precision grooving and fine turning that deliver exceptional rigidity for outstanding performance.

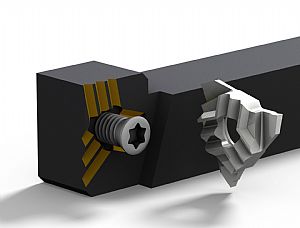

Applitec has developed its unique insert using their classic ‘ridge’ clamping technique with three teeth on the surface that lock the insert into position with the ridged toolholder. This clamping process drastically improves clamping strength with three protrusions on the toolholder mating perfectly with the insert. Beside enhancing rigidity for productivity and surface finish enhancements, the design offers three cutting edges on a triangular insert for improved cost and productivity per insert.

Applitec has created three new geometries with the TRIO-Line Series, this includes the GX geometry for high precision grooving to DIN6799 and DIN471 standards for applications such as circlip grooving. Additional geometries include the FT geometry for front turning and the GT geometry for grooving and turning. The three geometries are available in Applitec's HN wear resistant micro grain carbide grade for machining small geometries in brass, low alloyed aluminium and titanium materials.

For the light machining of steel, stainless steel and titanium alloys, Applitec offers the TRIO-Line in its HTA grade that is PVD coated for exceptional wear and fracture resistance.

The GX geometry for high precision grooving is available in widths of 0.26, 0.36, 0.46, 0.5, 0.57, 0.67, 0.77, 0.87, 0.97 and from 1 to 2mm in 0.1mm increments. With an accuracy of +/-0.01mm and a cutting depth from 1.5mm to 3.5mm in 0.5mm increments the series incorporates a 0.03mm radius to prevent edge breakages. With right and left hand inserts for the entire series, the toolholders are available with 8, 10, 12, 16 and 20mm square shanks.

The FT geometry of Applitec TRIO-Line inserts are available with a 3mm cutting length, a 0.03 or 0.08 radius and a 30 degree relief for highly productive front turning. The GT geometry for grooving and turning is available with cutting widths of 0.5 to 2mm in 0.5mm increments and cutting depths from 1.5 to 3.5mm in 0.5 increments with 0.03, 0.08 and 0.15mm radius choices. With wear resistant coated carbide grades combining with geometries that have been developed for extremely productive small part machining, the Applitec TRIO-Line range from Floyd Automatic is already making an impact throughout the manufacturing sector in Europe.