Floyd plunges into productivity gains with new CrazyMill

25 June 2020

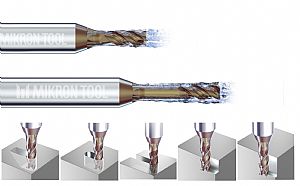

Mikron Tool has expanded its plunge-mill CrazyMill Cool P&S milling cutter program with the arrival of new dimensions to achieve even deeper machining cycles. Now available in the UK from Floyd Automatic, the new CrazyMill Cool P&S is characterised by the ability to plunge (drill) vertically into the material, mill slots or pockets into solid material in smallest spaces and conclude milling operations with finishing cycles.

While the milling depth in the short version (2.5XD) was based on the machining of keyways, the aim of the extended range is to be able to mill the deepest possible slots and pockets with a single tool, reaching more distant machining areas of a workpiece with a single tool. The new version of the solid carbide plunge mill is based on the same technology as the short version, transferred directly to the new line. Now, it is possible to plunge perpendicularly into the material and reach the maximum milling depth of 5XD. Despite its length, the milling cutter is extremely stable and at the same time, it impresses with its cutting speeds, chip removal rates as well as a long tool life and surface quality - all this from a milling diameter that starts at 1mm.

The cutting-edge geometry enables process stable and vibration-free ‘drilling’ (vertical plunging) even at a depth of 5XD. This not only prevents the cutting edges from breaking out, which is one of the central difficulties when drilling with a milling cutter, it also ensures excellent surface quality and extended tool life.

Even more than with the short version, good chip removal plays an important role at this depth. There is a higher risk that chips remain in the milling zone, are broken-up and thus damage both the milling cutter and the milled surface. The special cutting-edge geometry with CrazyMill Cool P&S and its extended chip area provides a remedy. It ensures perfect lateral chip removal during plunging and also tool stability during deep milling. Additionally, the integrated coolant ducts in the shank permit exceptional coolant flow and ensure an efficient chip evacuation, even in the tightest of angled spaces of deep pockets or slots.

Mr. Gotti, Head of the Technology & Customer Project Center at Mikron Tool confirms: "We work with this tool at high speeds and feeds and an axial infeed (ap) of 0.5XD, achieving an extremely high chip removal rate. For the user, this means up to 5 times shorter machining processes and a significantly longer tool life compared to other milling cutters on the market".

CrazyMill Cool P&S is now available from Floyd Automatic Tooling in diameters from 1 to 8 mm and for a maximum milling depth of up to 5XD.