Giving Motorsport better machining performance at Autosport 2016

26 October 2015

At Autosport 2016, OPEN MIND Technologies will be giving its UK exhibition debut to its latest CAM development, hyperMILL Version 2016.1. hyperMILL 2016.1 recently received its world premiere at the EMO Show in Milan where it caused quite a frenzy; and on Stand E1071 at Autosport, UK Motorsport manufacturers will get a taste of how it can improve machining performance.

OPEN MIND Technologies CAM software is already the industry leading CAM/CAD solution with seats installed at the majority of F1 teams and throughout their supply chain. The Autosport show at the Birmingham NEC from the 14th to 15th of January 2016 will give the industry benchmark CAM vendor an opportunity to present its latest developments.

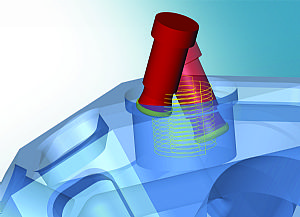

A particular highlight of the new version is the finishing strategy from the new hyperMILL® MAXX Machining performance package. ‘Tangent plane machining’ makes it possible to achieve machining time savings of up to 90%.

Extended functions for 3D and 5-axis machining tasks, new cycles for mill-turning and numerous innovations in hyperCAD®-S will complete the range of functions available in the new version.

‘Tangent plane machining’ offers users a major boost in efficiency for finishing planes and free-form surfaces. Using conical barrel cutters allows for larger path distances for the same theoretical scallop height. The OPEN MIND machining strategy takes advantage of the extremely large radius of the barrel shape, which allows for optimal inclination to the faces. This makes it possible to achieve considerably shorter machining times and a much improved surface quality. The innovative strategy is easy to program, highly efficient and reliable, thanks to the collision check performed on the toolpaths.

Toolkit with special strategies

Version 2016.1 sees OPEN MIND showcase the modular hyperMILL® MAXX Machining performance package. It offers a range of optional high-performance strategies for roughing and finishing. The package includes the HPC roughing module, currently called hyperMAXX.

Mill-turning with more performance

The mill-turning innovations and optimisation strategies will also promise better performance. The user interface is now even more transparent for making inputs easier. The new cutting edge position management feature will make it possible to better define the tool cutting edge and its position.

More CAD for CAM – hyperCAD®-S

hyperCAD®-S, the CAD system for CAM, is packed with many innovations and extensions in the 2016 version, including extended associativity with hyperMILL® and the new surface command for support during 5axis swarf cutting.

For more details on the latest version of hyperMILL or to book your demo at the industry's leading event, please contact OPEN MIND Technologies to see how we can turbo-charge your machine tool performance and productivity.