Gripping New High-Profile CAM solution

12 June 2012

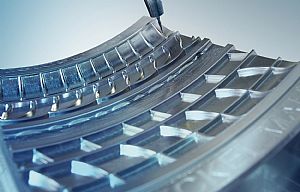

OPEN MIND has now developed a package of machining and automation strategies within its award winning hyperMILL package specifically for the requirements of tyre moulding. The new hyperMILL® tyre module has been developed to include functions that allow for moulds and models to be produced significantly faster and more efficiently.

With the new hyperMILL tyre module characteristic geometries can be defined as features and standard machining sequences that are saved to a macro database. The milling strategies for knifecuts and stone ejectors as well as other tyre production details, can thus be programmed faster as recurring machining sequences. The recurring arrangement of identical tyre sections is often described by way of a ‘tyre clock’. hyperMILL® uses this information for efficient programming. The user assigns the numbers of the individual pitches to the machining programs for this purpose, so that each pitch is programmed only once. The generated program is copied to the corresponding tyre mould segments on the basis of the pitch number. From this, the CAM software generates the complete segments automatically and toolpaths that go beyond the segment limit will be adjusted automatically by hyperMILL®.

The machining of the complex geometries in tread patterns is implemented by the automation technology in hyperMILL® in such a way that all tool movements are calculated as efficiently as possible. In a method that carefully calculates the machine tool and cutting tool, hyperMILL® automatically calculates collision-free tool positions. This means that machining operations with various tool orientations can be generated quickly and simply in a single operation. In particular, the automatic tool positioning substantially reduces the amount of time that is required to program the intricate structures of tyre moulds. The cutter also moves closer to the object. This is credit to the simultaneous, collision-tested movement that makes sure redundant movements are avoided.

The benefits of hyperMILL® are the machining strategies that the CAM software also fully exploits in tyre moulding. This starts with roughing, whereby the hyperMAXX® module supports the programming of effective machining paths. Of special interest in this context of tread patterns is also the machining cycle of the 5-axis rest machining. This cycle recognises all rest material areas and machines these in a single collision-free operation. As the hyperMILL tyre module produces particularly smooth movements, the sharp edges of the tyre moulds can be machined precisely with narrow tools without having to be reworked.