Groundbreaking and Field-tested hperMILL CAM Software

7 June 2020

OPEN MIND Technologies AG drives forward automation and the integration of additive manufacturing with the latest 2020.2 release of its hyperMILL® CAD/CAM suite. The developers at OPEN MIND have also implemented numerous functions to further simplify everyday machining tasks. hyperMILL® 2020.2 highlights include new strategies for the machining of cutting edges, upgrades for mill/turning, parametric design in hyperCAD®-S and the ‘hyperMILL® AUTOMATION Center Advanced’.

Plunge-milling cycles have been added to the 3D and 5-axis strategies for the machining of cutting edges. The material can be removed by plunging with 3-axis or 5-axis movements. The plunge-milling process reduces vibration for surface edges with steep walls, thus improving the surface finish. Any rest material machining using a smaller tool is easily calculated automatically from the previous job. With 5-axis machining, you can also reach undercut areas, such as for cutting edges. The tilted tool is specified by the lateral inclination and in order to optimally adapt the retract movement from the component, you can specify both a distance, circular or linear movement profile.

The proven – made even easier

hyperMILL® already offers strong mirror functions where the toolpaths for symmetrical components are recalculated on the basis of mirrored geometry data. Now with version hyperMILL® 2020.2 OPEN MIND enhanced the functionality. The ‘Mirror Path’ function enables simple mirroring of the previously calculated toolpaths. Here, the machining direction is also mirrored and climb milling therefore becomes conventional milling. Users benefit now from shorter calculation time and improved process reliability. Both methods are available to provide the ideal solution for all situations.

The user-friendliness of hyperMILL® has been improved even further. For a faster search in the tool database, the filter properties are now integrated into the top level of the user interface, meaning they are always visible. The filter properties are pre-loaded with the material from the job list and the spindle holder from the machine properties. Other tool parameters and custom fields can also be used with the tool database filter (video). Feature management has also been improved to save time during programming. Now you can quickly locate special feature types such as holes or pockets even faster due to a new text search. These filter functions allow nimble access through a large customized tool database.

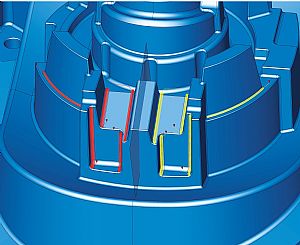

Mill/turning

Round inserts, as well as rhombic, T, and W inserts can now be used with 3-axis simultaneous mill/turning. There is now a function to control the approach and retract movements by applying user-defined curves for all turning strategies. This option unlocks the potential for productivity and programming optimization on workpieces with areas that are particularly difficult to reach – all movements are still collision checked, despite the manual operations.

hyperMILL® AUTOMATION Center

The ‘hyperMILL® AUTOMATION Center’ has been upgraded in hyperMILL® 2020.2 and OPEN MIND now offers an optional advanced version that boasts numerous additional functions and extensive templates. These templates allow the user to define and standardize complex processes independent of the specific geometry from any one CAD model.

All the individual steps for data preparation and programming, right up to simulation and NC program generation are defined. Once you have defined a manufacturing process, you can apply it to a new model and have it automatically executed. If there are any decisions that cannot be made with confidence within the automated process, the user can be prompted to make the relevant choices during the automation sequence. The user is interactively guided through the individual process steps, making it possible to program the component in a fraction of the time it would normally take.

Parametric designing with hyperCAD®-S

Components can now also be modeled directly in hyperCAD®-S parametrically. This function is of particular interest for fast, production-related designs. For example, you can design a fixture plate parametrically and change dimensions to define different variants to the base model very quickly. It can be simultaneously used in parametric mode in hyperCAD®-S, while static models can also be placed inside the same dataset. Similarly, you can use a static solid model in parametric mode and add parametric features to it for a hybrid approach. Parametric geometry data used in hyperMILL® is associatively linked, and when there are any changes, it is updated automatically