Hip Joint Manufacturer Selects OPEN MIND CAM Software

Based in lslikon, Switzerland, Jossi Orthopaedics AG is a world leading manufacturer of orthopaedic implants and the critical communication from development through to series production, delivers workpieces that are in demand all over the world. Playing a critical role in the development to production process at Jossi Orthopaedics is the hyperMILL® CAM package from OPEN MIND Technologies.

Orthopaedic implants are without doubt state-of-the-art, high-tech developments that allow patients to become pain free and restore as much mobility as possible. Manufacturers of implants systems work directly for patients. These products are not luxury goods and manufacturers have to work with complex geometries and challenging materials such as titanium alloys, cobalt-chromium and high-alloyed steels.

Working in a country regarded as the global benchmark in Orthopaedic production, Jossi Orthopaedics AG has mastered the materials and all of the processes required to machine them. The company’s roots date back to the founding of Hans Jossi Präzisionsmechanik in 1957. Hans Jossi manufactured various kinds of parts and mechanisms and quickly made a mark

through his ability to machine challenging geometries and materials.

Among other things, Jossi built robust, durable presses and received a request in the 1970s regarding whether it would be possible to reshape titanium. “At that time, titanium was not practically suitable for reshaping. Nevertheless, Hans Jossi and his team managed to develop a process for the deep drawing of titanium,” says Dr Martin Schmidt, responsible for the International Markets segment at Jossi. This process made it possible to save a lot of money compared with complete machining from solid stock. Around 70% of costs involved in the Jossi process are lower than for pure machining (material costs and processing costs). This created a competitive advantage, which lead to a decision to start manufacturing implants.

Today, the Jossi Group employs around 200 people and is divided into Jossi Orthopaedics AG, Jossi AG and Jossi Systems AG, under the umbrella of a holding company.

Jossi Orthopaedics produces components for orthopaedic implants and corresponding surgical instruments. “We define ourselves as a pure supplier. The products always carry our customers’ name, and they are all well-known orthopaedic companies,” says Dr Martin Schmidt. On the one hand, the Swiss specialists work according to customer specifications, and on the other hand, they continuously offer new manufacturing technologies and solutions.

“Our comprehensive expertise, command of the processes and use of the latest tools allow us to undercut competitors by a factor of three when it comes to the production time of parts and hyperMILL contributes to this,” says a proud Dr Schmidt.

Easy to use

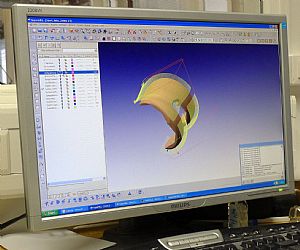

hyperMILL® allows users to program any type of machining – 2D, 3D, HSC and 5-axis milling, as well as mill/turning – from within a standardised user interface. After all, there are hardly any modern components that require only one type of machining and this is particularly appealing to Jossi.

Broad spectrum of machining strategies

Jossi Orthopaedics also uses turn-mill centres from Mori Seiki and a large number of machining centres from Hurco and Hermle to machine implants and tools. In order to find the best-possible CAM system for their programming needs, it was necessary to undertake a selection process that also reviewed two other CAM systems under consideration. “hyperMILL® came out on top in the end, as it provides simple and efficient operation during 5axis programming,” reports Midhat Dedovic, Head of Multi-Axis Manufacturing at Jossi Orthopaedics.

There are now two hyperMILL® workstations in use for manufacturing and another one is used to train apprentices. “When it comes to the two production workstations, we use everything the system has to offer, apart from the special applications,” explains Midhat Dedovic. This results in a solution that the machines can optimally exploit for every type of part, thus contributing to short manufacturing times.

Jossi uses the tool database contained in the CAM software as much as possible. It makes it possible to completely import tools, define individual tools and custom-assemble complete tools including holders. In addition to the material-specific cutting data, users can also create various profiles for each tool defined in the database. This way, different applications can be pre-defined and then selected in the job steps – even for the same workpiece and cutting materials.

To simulate the CAM programs, Midhat Dedovic and his colleagues stored the Machine models in the CAM system. This way, it is possible to check the programs created, either in terms of the toolpaths created or in terms of complete workspace and machine monitoring. “We alternate in this respect. For 5axis programs, we perform collision checks directly during programming. For 2D paths, the check is performed at the end as part of the complete simulation," says Dedovic.

The CAM experts use existing simplification and acceleration options by copying jobs or the entire job list. There are five sizes for the components for knee joints, for example. When it comes to the job, Size 4 is identical to Size 5. Here, copying the job list helps the user to progress quickly.

“We also use automatic feature recognition to speed things up,” explains Dedovic. Automatic feature recognition detects geometries from solids and surface models, such as holes, stepped holes with and without threads, as well as open and closed pockets. Parameters are automatically generated that are required for the programming of machining strategies and for tool selection. Jossi Orthopaedics uses this advantage when it comes to inserting holes on free-form surfaces that can be placed anywhere.

Summary

The experience that Jossi Orthopaedics has had with hyperMILL® and OPEN MIND has been very positive: “I’m fully satisfied with the product, so much so that I can say that I don’t want to use any other CAM system. We are also delighted with the support provided by OPEN MIND, both from Switzerland and the head office in Germany - its excellent.,” concludes Midhat Dedovic.