Hydrafeed Offers Complete Automation Solutions With New Agency

2 March 2015

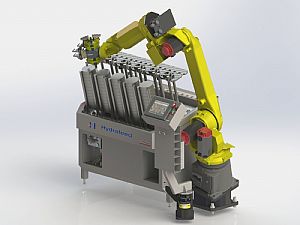

As the UK's leading barfeed manufacturer for turning centres, Hydrafeed has now cemented its benchmark position for improving productivity of lathes by becoming the UK's exclusive agent for the Robojob series of automated loading and unloading systems.

Adding to its barfeed, X-Tract and Rota-Rack units for feeding and catching parts on turning centres, the new Turn-Assist and Mill Assist Series of automatic loading and unloading systems will now enable Hydrafeed to offer complete automation for turning and machining centres.

The unique Turn-Assist system allows the unit to be deployed on CNC turning machines of all brands of both existing and new machine tools. The interface of the Turn-Assist system is characterised by its user-friendliness, as its design requires no specific robot knowledge for operation. Most importantly, the Turn-Assist can be set up in less than 5 minutes.

With the Fanuc robot set up in an inclined position, the machine-opening remains fully accessible to the operator, as does the swarf tray. This provides easy access for machine cleaning and tool changes. can also be opened as normal for emptying or maintenance.

The Robojob software even proposes which type of gripper or gripper fingers should be used. The Turn-Assist system uses a unique patented servo-operated stacking table, which helps to realise optimum use of space for varying work piece sizes. No matter what the dimensions of the part to be processed (Ø23mm to Ø180mm), they fit perfectly on the stacking table. This impressive system can reduce operator costs, improve productivity and consistency whilst also permitting cost effective lights-out production.

Hydrafeed can also provide these benefits to manufacturers with machining centres with the extremely flexible new Mill-Assist system. Like the Turn-Assist, the milling automation system can be adapted to all brands of CNC machining centres with the automation experts from Hydrafeed and Robojob providing a full turnkey solution with configuration data that can be loaded and stored for repeat assignments

The Mill-Assist E system can be set up in two ways with either a ‘Front set-up’ or a 'Side set-up’. In both cases the machine-opening remains completely free, thus the normal access of the operator is not obstructed. Security based on a peripheral scanner can replace disturbing fencing. For the ‘side set-up’, you can either choose a transparent screen with sliding doors, or an open entrance guarded using a light curtain.

Robojob utilises a unique ‘’Cube’’ gripper concept that can quickly attach various types of grippers, this concept is suitable for both adjustable clamp and vacuum grippers, so all types of work pieces can be gripped. The Mill-Assist E system uses a unique configurable and patented input and reception plate. This plate is suitable for small and medium-sized parts from ø23mm up to ø450mm.