Improving layer by layer: Materials optimisation at Walter

2 November 2025

Metalworking appears to make daily advances in innovation, focusing on continuous optimisation. Insights into the development process of the new Walter cutting material grade, Tiger-tec® Gold WPP35G, demonstrate the strategic and practical challenges of refining established solutions to meet specific application needs.

Continuous improvement instead of revolutions

When companies launch a new product, there is no margin for error in marketing, even in the metalworking industry. The new holemaking grade from supplier X elevates process reliability to unprecedented levels; the new cutting material grade from supplier Y surpasses the previous model or competing products. If you only focus on marketing, innovations in the metalworking industry come thick and fast - and it doesn't seem particularly challenging to develop and introduce increasingly better tools consistently.

However, every day, users of cutting tools understand that the reality is, of course, somewhat different. In metalworking, the wheel is not reinvented every few weeks; instead, the industry is characterised by ongoing improvements across manufacturers. In fact, more than a thousand patents related to mechanical engineering are registered annually in Baden-Württemberg alone (source: Patent-Atlas Baden-Württemberg 2024 & DPMA Patents 2024). Most of these are enhancements to existing products, technologies, and processes. For example, the geometry of a carbide drill is further refined using new digital technologies such as 3D modelling and simulations, or machine learning, to minimise the risk of tool breakage when machining challenging materials or deep holes, through improved chip removal, vibration control, or other optimisations identified by developers.

Innovative strength: the Walter strategy

Optimisation is central to the strategy and approach of most research and development departments within machining. Manufacturers gravitate towards the specific needs of their applications. In particular, metalworking companies face intense cost pressures. They are not only exploring new processes and the associated investment costs, but also seeking to unlock optimisation potential within existing processes and gradually enhance them. For example, a new optimised indexable insert grade, such as the Tiger-tec® Gold WPP35G launched by machining specialist Walter from Tübingen, often advances the company more than a completely new technology.

The development process for the new insert grade exemplifies the strategic and practical parameters within which the innovation-focused research and development departments operate. Just under a third of the products in the Walter portfolio are less than five years old. With a new sales ratio of around 30%, the machining experts from Baden-Württemberg rank among the top providers of innovative machining solutions. The number of employees in Walter's development department is relatively high compared to the company's size. This is where the company's goal to deliver solutions that keep customers at the forefront in terms of cost-effectiveness and efficiency is realised. Walter typically expects a lifespan of seven to nine years for cutting tool materials before launching the next generation. Each new iteration of tools must offer substantial improvements over its predecessor or address specific new application challenges. In recent years, for example, the proportion of light metal and HRSA alloys in metal machining has steadily increased, and Walter supports this trend with innovative machining solutions.

The basic usage area of the new Walter grade Tiger-tec® Gold WPP35G, on the other hand, is very traditional. The grade has been developed for rough milling of steel and cast-iron materials. The ISO P and ISO K material groups still account for the largest share of the world's machined materials. With the previous Tiger-tec® Silver WKP35S generation, Walter had a solution in its portfolio that was extremely successful due to its wide range of applications and performance. The grade was one of Walter's best-selling grades in this application field for many years. Improving this popular grade, which is also a central component of many of Walter's customers' production processes, was a real challenge. The result of an intensive process, in which Walter application engineers were also involved from the onset, is the new Tiger-tec® Gold WPP35G grade. As a prototype, the solution that has now been launched has proven its qualities in numerous field tests under realistic operating conditions at real Walter customers. According to Walter, the Gold generation once again significantly increases the performance of the tried-and-tested Tiger-tec® Silver solution, particularly in terms of wear resistance, process reliability and tool life. Here, the WPP35G outperforms its predecessor by an average of 35% when machining steel, while the increase in performance is over 15% when machining cast-iron components.

Optimum performance and wear resistance

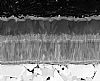

To achieve this level of efficiency, Walter's development engineers optimised the entire physical structure of the indexable insert. The technological centrepiece of the Tiger-tec® Gold generation is the highly textured, multi-layer MT-TiCN structure. MT-TiCN stands for a Titanium Carbon Nitride coating that is applied to the carbide substrate using a medium-temperature CVD (Chemical Vapour Deposition) process. This technology enhances resistance to abrasive wear, as well as the elastic properties of the coating and its adhesion.

A highly textured layer of aluminium oxide (Al2O3) is applied on top, and in this process, the crystals are given a uniform, precise arrangement. This homogenised crystal structure has a significantly improved mechanical strength compared to cutting tool materials with non-directional structures. At the same time, this Al2O3 layer acts as an extremely wear-resistant heat shield that protects the underlying carbide from the extreme temperatures that occur during the milling process. The final characteristic, the gold-coloured TiN layer on the flank face, not only serves as a visual distinguishing feature but also optimises the visual detection signs of wear by the user, which enables timely tool change planning and thus reduces unplanned downtime.

Alongside the highly developed texturing of the individual layers, the multi-stage post-treatment significantly enhances the exceptional wear resistance of this CVD grade, which was specially designed for milling. The innovative process microscopically smooths rake faces, reduces friction, and minimises build-up on the cutting edge. Simultaneously, it increases the toughness of the cutting edge and improves resistance to chipping. The high process reliability of the WPP35G makes it the ideal solution for reducing labour requirements in mass production environments. It can be used for medium to good machining conditions, both in dry machining with steel and with lubricants, across all standard Walter milling cutters from the M4000, Walter BLAXX, and Xtra-tec® XT lines.