Industrial Design: It's a must for Machine Builders

7 November 2013

For many, industrial design is a necessary evil and for others it is essential. Often, it is dismissed because it involves additional cost and is not essential for the operation of machine tools. Customers also neglect it because it often involves additional cost without bringing any concrete improvement in performance.

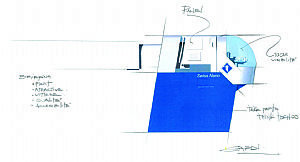

Tornos has developed a number of new designs that mark a paradigm shift in machine tool design and development. Recently, the Tornos MultiSwiss, EvoDECO 32 and Almac BA1008 machines have all been designed by Enrique Luis Sardi, Director of Sardi Innovation.

Highlighting the key aspect of machine tool design, Mr Sardi says: "Design is often neglected within the industry, however it is a key differentiator that can bring real economic benefit. Innovation through design will bring you real added value compared to your competitors, and will also strengthen your brand image. We offer much more than design, we are a team set up to offer innovation and bring new, iconoclastic ideas to entrepreneurs and large companies. We do not simply design beautiful machines, we support our customers in their search for solutions that ensure their product is more than just uniquely better, it is unique. Our mission is to turn crazy ideas into concrete, profitable business opportunities. We always have our eyes and ears open; it is a constant quest and battle to keep a company at the cutting edge; we need to plan the aesthetic innovation process almost two years in advance. The objects are simply the final realisation of this process."

Confirming the importance of a synergy between ergonomics and design, Mr Sardi says: "Design and ergonomics are just two sides of one reality. The design cannot precede the function, but it must be able to improve it as much as possible. Take the SwissNano, for example: You have a unique product combined with a range of ergonomic functionalities, the most striking is the bubble giving the operator 180° access to the machining area. The control is on a pivoting arm ensuring perfect ergonomics during adjustment operations. The top of the enclosure houses a support that allows tools to be deposited on the top of the machine without falling or damaging the machine. The feeder is integrated inside the machine. These layout issues would not be possible without in-depth analysis of the product and its everyday use. But ergonomics do not prevent you from having an attractive design; in fact, contrary to popular belief, a well though-out design often allows the manufacturing costs of the enclosure to be reduced."

Defining how projects progress, Mr Sardi beleives: "The projects I work on highlight the collective aspect of my work. I balance the energies of my innovation group in Milan with the needs of our customers. My goal is to unite the project team around common values, to get past the stage of thinking 'its not possible', to analyse each constraint to see whether they are actually necessary and, if they are, then to work with these constraints. Through my actions, I hope to lead both the team and the project towards the road to innovation. Design is hidden in the details and is fundamentally the result of teamwork. We are working on a number of new projects with Tornos and these innovations will be launched in the near future."