Innovative Thread Whirling from NTK

2 September 2014

Thread Whirling has become a popular process for Swiss machines, especially among bone screw manufacturers. Although most sliding head turning companies agree that thread whirling delivers outstanding productivity with the highest level of efficiency when compared to conventional single point threading, not all engineers understand the 'Real Thread Whirling' process.

NTK first released thread whirling tools with 9 inserts back in 2008. The 'Bone Screw' is a major part produced by the thread whirling process and it is quite unique, compared with the other industrial screws, since there are no female threads to mate. Bone screws are attached directly into human or animal bones for medical repair applications. The screw is not expected to be loosened at all once it is fixed in place. The characteristics of bone screw are a larger pitch size, and a larger screw depth and length, as the key function is for the thread to be tightened into bones rigidly and as quickly as possible.

As a result of this unique nature, inspection of screw forms has become extremely difficult. Due to the larger helix angle to make a high pitch thread form, you cannot visually see the cross section with a common optical comparator. What you can check with an optical comparator are only a peripheral or bottom diameter of the thread.

The only way to measure the real thread form of a bone screw is to inspect it with a CMM. However, few manufactures use CMM measurement for inspection after machining, opting for visual thread form and surface roughness inspection. Another surprise for NTK, is the fact that manufacturers with the very latest machines and well experienced staff, make small adjustment on a helix angle or pitch size when they canít get ideal thread form. As you may understand, if you change the helix angle or pitch size, the thread form itself could be totally out of print specifications.

Why does this happen? One factor comes from the unique nature of the bone screw - no female thread. If the thread form is made close enough to the print, the screw can perform its function to be tightened rigidly to the bone since there is no mating surface.

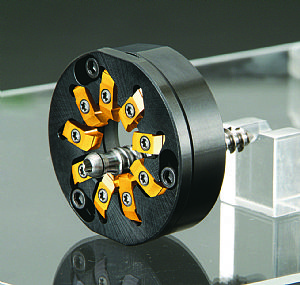

Thread whirling inserts are set on the round cutter body and the cutter is attached to the spindle that is tilted with helix angle. Then, the spindle revolves at a higher rotation of approximately 3000rpm, while bar stock revolves in the same direction but at a much slower rate like 10-30rpm. In this rotating process, each thread whirling insert machines the bar stock while they rotate much faster than the bar stock. The spindle and the inserts tilt to make thread form, and the inserts shave the bar stock at the center of the bar as well as the upper or the lower side of the bar stock.

Conventional, single point threading inserts can be designed with exactly the same thread form as the thread because it always machines with regards to the center of the bar stock. On the other hand, thread whirling inserts cannot be designed with the same concept as the actual machining point always varies on the upper or lower side of the bar. Many thread whirling inserts are designed with the identical methodology as single point threading. With this incorrectly designed thread whirling process, bone screw manufactures are frequently required to re-make the inserts. NTK thread whirling does not require such guesswork or process manipulation. Thanks to the design capability of NTK's inserts the leading Japanese manufacturer can obtain perfect threads right from the start. This excellent designing technology is now patented.

Recently, to shorten surgery hours, bone screws with double lead threads have become more popular. This industry trend is creating another challenge for the bone screw manufacturers. Producing double lead bone screws requires longer machining time than single lead threads. Most manufactures machine the 1st lead within the guide bush length and then machine the same length of 2nd lead, so that guide bush wonít lose the bar stock. As a result, the process is repeated a few times until the full length of the bone screw is machined. Single pass machining of the double lead bone screw without considering guide bush length, is the best solution to improve productivity. However, it is literally too difficult in thread whirling. To enable single pass machining of double lead screw, both inserts must have a different geometry on 1st and 2nd thread even though both 1st and 2nd thread form of the screw is identical. This is simply because thread whirling machining is done at, upper, and lower center of the screw. This fact creates difficulty for all cutting tool manufactures in designing double lead thread whirling inserts.

NTK thread whirling technology and highly accurate insert grinding can produce the perfect thread whirling inserts first time to permit single pass machining. Provided the machine is equipped with the correct helix angle setting, correct tool setting and NTK thread whirling system, end users can experience 'Real Thread Whirling' to produce the perfect thread form screws.