ITC ensures precision with BIG KAISER tightening fixture

2 January 2018

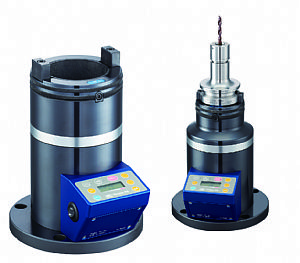

At EMO 2017, BIG KAISER, a global leader in premium high-precision tooling systems and solutions for the metalworking industries, announced the global launch of the new Torque Fit, a tightening fixture for collet chucks with an integrated torque indicator. The Torque Fit that will now be available in the UK from Industrial Tooling Corporation (ITC) will make it easy to ensure that a collet chuck is tightened correctly.

The aim of this new system is to help manufacturers achieve high-precision machining by notifying the user of a correctly set torque value via an audible buzzer. This tightening fixture was developed to replace multiple torque wrenches and comes with adapters for all common machine tool interfaces such as HSK, SK, and BT.

For maximum convenience, torque values of all the BIG KAISER-made collet chucks that are available from ITC are preset. The user can, however, set the torque to any value of their own choosing from 4 to 80Nm. The minimum read value is 0.01Nm at less than 10Nm, and 0.1Nm at 10Nm or more. The Torque Fit includes an error LED to indicate overtightening.

Commenting on the new device, VP Sales at BIG KAISER, Giampaolo Roccatello says: “High precision is vital for machining applications. The Torque Fit plays a relatively small yet essential role in ensuring that high precision is simple and quick to achieve in real-world conditions. It is far more economical for the customer to purchase only a single Torque Fit instead of multiple torque wrenches."