ITC Gets a Groove-On With New BIG KAISER Line

27 July 2016

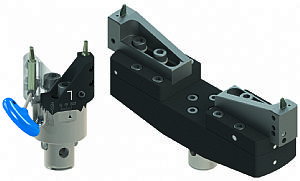

Now available from Industrial Tooling Corporation (ITC) is the new range of BIG KAISER insert holders for face grooving operations. The new accessories are specifically designed to fit the BIG KAISER large diameter Series 318 and Series 319 SW twin-cutter boring heads.

Providing the ultimate system flexibility, the new face grooving system can be used as either a single or twin cutter grooving tool for diameter ranges from Ř53mm to Ř3m. The design allows for a grooving depth up to 12mm, with a minimum width of 2mm and a maximum of 9.5mm.

Face grooving with boring tools is generally more efficient than milling with circular interpolation, especially when manufacturing grooves of large diameters. Also, whenever a surface for a sealing application is required, there is no other acceptable or accurate option than to use a face grooving setup.

Using the boring tools as twin cutters with a simultaneous adjustment in radius and length allows the feed rate to be increased considerably. Using the cutters in diameter offset operation enables a groove width of up to 12mm. It also allows both inside and outside diameters to be adjusted separately within the smallest tolerances. Both cutting edges can be adjusted easily to the same length. This is credit to an eccentric bolt mechanism with clear direction indication.

“The BIG KAISER products give our customers an unparalleled combination of quality, precision and ruggedness,” says ITC's Neil Vine. “These new face grooving holders uphold that tradition while adding extra options to the applications where possible. This is particularly the case with the SW twin cutter and large diameter Series 318 system.”

BIG KAISER is a worldwide leader in high-precision tooling systems and solutions for the metal cutting industry. The products available from ITC guarantee extreme accuracy and repeatability with the utmost care and attention upon product quality.