New High Precision PCD Turning Tools from NTK

23 June 2015

For high precision turning of aluminium, aluminium alloys and brass, NTK Cutting Tools has now introduced its new line of PD2 turning inserts that are PCD tipped.

The impressive new PD2 range of inserts have been manufactured from a super micro grain PCD that enhances edge sharpness and chipping resistance for the end user. This excellent edge control is further improved by a high rake angle geometry. Composed of a sub-micron PCD grain, the PD2 improves insert toughness for the end user, which makes it ideal for interrupted and continuous machining.

Outperforming alternate grades, the new PD2 is well suited to semi-finish to finish machining operations with impressive productivity credentials - cutting beyond 220m/min with depths of cut up to 0.2mm. Due to its high speed machining capability, the new PD2 insert range is best suited to running with coolant that can support heat dissipation. When working at the specified cutting parameters, the PD2 extends tool life and wear resistance by up to 50% when compared to leading grades from alternate vendors.

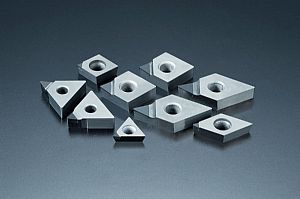

As for the geometry of the new PD2 line of inserts, the grade is offered in positive formats with the CCMT, DCMT and TPMT designations and as a negative insert with the CNMX, DNMX and TNMX. Corresponding tool holders can be provided by NTK. Furthermore, the various geometries are offered with the choice of a 0.2, 0.4 or 0.8 corner radius to suit the specific demands of the customer.