NTK Develops New Ceramic Grade For Turning

5 February 2014

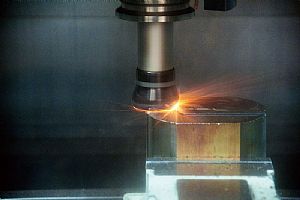

For high performance turning, Japanese cutting tool manufacturer NTK has now developed a new ceramic insert grade that delivers remarkable productivity and tool life. The new SX7 grade has primarily been created to offer improved notching and flank wear resistance when compared to Whisker ceramics and competitor ceramic products.

The new sialon SX7 ceramic grade is ideal for the machining of difficult to machine materials such as Inconel 718 and 625,Waspaloy, Udimet, Titanium and other hard to cut materials. Suitable for semi-finishing and profiling processes, the new round SX7 inserts can also be utilised in NTK's diverse range of milling cutters. As the new benchmark in high speed cutting, the SX7 grade can machine at speeds beyond 240m/min, giving the end user remarkable productivity benefits.

The SX7 grade is currently available with three insert types. There is a round insert with a negative geometry for high feed roughing operations whilst a round insert with a positive geometry is available for detailed machining and finishing operations. Furthermore, NTK has created a grooving insert that enables customers to conduct efficient grooving and parting with speeds and feeds that far exceed that of typical carbide inserts.

The SX7 inserts are available as a solid round type or with a notch for enhanced clamping rigidity, which is critical for high speed ceramic machining.

The notch in the inserts fit perfectly with the clamping screw system to extend tool life and productivity beyond that of competitor products. The negative and positive insert designations are compatible with NTK's CRDNN toolholders. The robust toolholders are available with toolholder heights of 20, 25 and 32mm with a width of 10, 12.5 and 16mm. These optimal toolholder dimensions enhance the rigidity and strength of the insert to eliminate potential vibration. The toolholders are available in overall lengths of 150 or 170mm and they incorporate an innovative quick release single screw clamping unit that works in harmony with the insert seat design to optimise rigidity and the resulting tool life.

For grooving operations, NTK's CRDCN toolholders can accommodate the new SX7 inserts. Like the toolholders for high feed turning, the CRDCN is a robust toolholder with an overall width and height of 25 or 32mm and an overall length of 150 or 170mm depending upon the customer requirements. Additionally, the CRDCN toolholders incorporate a single screw clamping mechanism that locates the notch on the insert to drastically improve rigidity.

Commenting upon the launch of the new SX7 ceramic grade, NTK's General Manager, MR Peter Ward comments: "This new grade is a technology breakthrough that can extend productivity by a factor of 10 when compared to carbide tooling. This marks a paradigm shift in the productivity benefits and machining strategies for automotive and aerospace manufacturers. Furthermore, the notched insert design is not available from competitors, so our cutting tools and insert grades eliminate all insert movement. This is a critical factor with ceramic inserts as any vibration or movement can cause instant insert failure."