NTK Has a New Groove With Next Generation Turning Line

30 September 2015

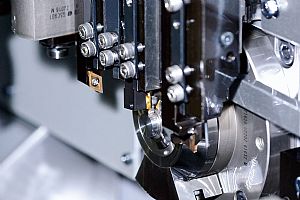

NTK has now extended its comprehensive tooling line for turned parts manufacturers with the introduction of its new GX Series of chipbreaker inserts for groove turning applications. Claimed to be the world's first triangular 3D chipbreaker geometry in the large 32 size range, the new GX range has been developed to improve surface finishes, chip removal and above all, remove any remaining swarf at the end of the grooving process.

Any turning shop experienced in grooving operations will have experienced swarf gathering around the tool holder or swarf remnants left in the finished groove. To eliminate these issues when turning materials such as free cutting steel, carbon steel, alloy steel, stainless steel and titanium alloys, NTK has introduced this revolutionary new geometry. The insert geometry consists of a chipbreaker design with a central protrusion that shapes and curls the chips to reduce cutting forces and improve swarf evacuation. This impressive new geometry permits side machining with astounding chip control. This capability gives the end user improved productivity and flexibility when turning grooves of varying depth and width. To assist this side machining capability, the new GX Series of inserts incorporate a polished outer periphery.

The PVD coated carbide inserts are available with a cutting depth of 2 or 3mm with a corner radius of 0.05, 0.1 or 0.2mm to minimise edge breakages and extend tool life when machining difficult to cut materials. The inserts are offered in cutting widths of 0.75, 0.95, 1, 1.5, 2 and 3mm.

To enable customers operating all machine types to benefit from the new GX Chipbreaker Series, NTK has made the new geometry available with a range of toolholders that include its GTT, Y-GTT, DS-GTT, CH-GTT, GT-OHH and Y-GTT-OH. What this means for the end user, is the option of toolholders in right or left hand designation with (or without) through coolant. Furthermore, the square shank toolholders are offered in sizes of 8, 10, 12, 16, 20mm. Additionally, the round shank Y-GTT-OH toolholder is supplied in diameters of 13, 15, 18, 19, 21 and 24mm for larger and more robust turning centres. Each of the respective toolholders are offered with a range of overall toolholder length options. These include 80, 100, 120, 125 and 150mm for turning centres that are either restricted for space or alternately for customers looking for a long tool overhang option.