NTK Sticks It To The Competition With New Boring Tools

6 March 2014

Profiling, grooving and boring operations for small component turning has now been significantly simplified by NTK with its new Stick Duo range of double ended solid carbide boring bars. With the majority of world's sliding head turning centres manufactured in Japan, NTK has worked closely with these manufacturers to develop the new Stick Duo boring bars that can dramatically reduce cutting tool costs and tool inventory whilst improving productivity and tool life.

The new Stick Duo is available with three options; an SBFS type carbide bar for boring, the SBFB type for profiling and the SBG type for internal grooving operations. The SBFS type is suitable for bores and holes from two to 8mm diameter with boring bar diameters increasing in 1mm increments. Incorporating an ultra sharp cutting edge with a 5 degree clearance and rake angle, the SBFS is available with an overall length of 50, 60, 70 or 80mm to suit the machining depth demands of the customer.

The SBFB boring bar for profiling incorporates NTK's F Style chipbreaker that discharges chips away from the cutting area to demonstrate exceptional chip control and evacuation. Developed for profiling small bores from 2 to 6mm diameters, the SBFB has proven itself as the turning tool of choice for detailed internal work on small components. The SBFB includes a corner radius of either 0.05 or 0.15mm to extend tool life and prevent edge breakages.

The internal SGB type grooving bar is available for bore diameters from 3 to 8mm with a groove width of 0.5, 0.75, 1, 1.5 and 2mm. The clearance between the boring bar and the cutting edge allows a grooving depth of 0.8, 1, 1.2, 1.8 or 2.2mm depending upon the groove width selected by the customer. Like the two other styles, the SGB can be provided with overall bar lengths from 50 to 80mm and with corner radii of 0.05mm to prolong tool life and deliver consistent machining performance.

The Stick Duo range is manufactured from NTK's ZM3 carbide coated grade that extends tool life. This outstanding tool life is further extended by the three cutting edge geometries that include the SHFS-H for mirror finishes, the SHFS-S with an extremely sharp cutting edge and chipbreaker plus the SHFB-F that improves chip control by feeding the swarf away from the cutting area.

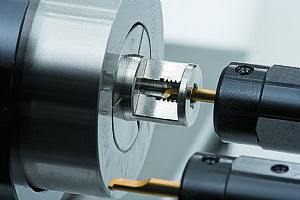

The Stick Duo is available with the NBH and the Stick Duo Hyper tool holder. The exciting new Hyper tool holder incorporates a positional clamping screw, a side clamping screw and also a clamping screw at the top of the shank that enable the end user to access and remove the boring bar from all sides. This is particularly suitable for small turning centres with limited access to the work envelope. However, the most innovative feature of the Stick Duo Hyper tool holder is the tool overhang ball screw that enables the customer to set and adjust the overhang length of the boring bar.

The NBH tool holder has the option of a straight shank or a tapered shank end that provides clearance for extended reach. The straight shank tool holder is offered with diameters from 15.85 to 19.05mm and an overall length of 100 or 125mm. Likewise, the tapered shank end tool holder is available with diameters from 20 to 25.4mm with an overall length of 125mm. To enhance rigidity, location and performance the NBH tool holder has three clamping screws.