OPEN MIND 'MAXXimises' CAM Performance for MACH 2016

11 January 2016

AT MACH 2016 on Stand 5965, OPEN MIND Technologies will be giving its UK exhibition premiere to the latest version of its award winning hyperMILL® CAM software. The new hyperMILL® Version 2016.2. will introduce a raft of innovative new CAM strategies that will greatly improve roughing, finishing and drilling performance. One of the core highlights of the new hyperMILL® suite will be the 'MAXX Machining' performance package.

The new hyperMILL® MAXX Machining performance package offers three powerful modules that help companies realise significant optimisation potential in roughing, finishing and drilling applications. The first module is fast roughing and this includes numerous cycles for milling in trochoidal tool paths, something that results in fast and reliable HPC machining. With a dynamic feed-rate adjustment that performs according to actual cutting conditions, customers are assured of achieving milling cycles with the highest possible feed-rates at all times. This results in optimal milling paths with maximum material removal and the shortest possible production times. High-speed roughing of both prismatic and curved component faces is supported.

Incorporating innovative algorithms, this feature ensures that a constant chip volume is always removed by each tooth of the milling tool. This delivers high utilisation rates without exposing the tool to undue stresses, resulting in roughing speeds that are 20 to 70% higher than before. OPEN MIND has made this fast roughing method available for all types of machining from 2D to 5X simultaneous.

The finishing module of the hyperMILL® MAXX Machining performance package has been introduced for the optimum application of tool characteristics in combination with trendsetting CAM strategies. This module includes pre-finishing and finishing of planes and free-form surfaces with various barrel cutters. Significant time savings can be achieved with a simultaneous improvement in surface quality. These benefits are accomplished with CAM strategies that use the special shape of the tools to best advantage.

The finish depends on the step-over distance and tool radius. The quality of a workpiece surface decreases as the line increment increases and improves as the tool diameter gets larger. This means that if you want to shorten the machining time by increasing the infeed rate, for example 5mm instead of 0.5mm, the tool radius has to be increased several times over to obtain a high surface quality at the same time.

As the tool diameter cannot be increased at will, barrel cutters only work with a section of the desired tool diameter – a circle segment. Larger step-over distances can be realised due to its bigger radius, while achieving high quality surface finish. The hyperMILL® MAXX Machining finishing module realises fast, high-quality machining jobs with general, tangential and tapered barrel cutters.

Taking Savings to Another 'Plane'

With ‘tangent plane machining’, OPEN MIND has developed a special CAM innovation for plane machining. Time savings of up to 90% can be achieved when using conical barrel cutters. Path distances of 6 and 8mm are possible with the large radii of the conical barrel cutters. This results in optimal surfaces and longer tool life. ‘Tangent plane machining’ is equally well suited for straightforward and hard-to-reach planer faces. Tool paths are generated automatically and checked for collisions.

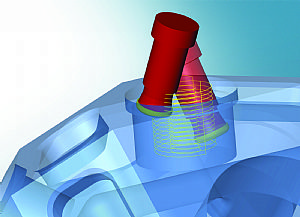

5-axis helical drilling

Another new performance strategy that is fresh from its World Premiere at EMO is the ‘5-axis helical drilling’ cycle. To be introduced at MACH 2016, this cycle enables holes to be machined easily and efficiently. This cycle involves helical milling with a forward lead angle. A tilt angle to the side is then used as part of collision avoidance process. The advantages are that only one tool is needed for different drill diameters. Pre-drilling is not necessary and the strategy is very well suited for materials that are hard to cut. The process features safe chip removal and reduces stress on the tool. Practical tests have shown that, with ‘5-axis helical drilling’, the machining time can be reduced by 20 to 25% compared to conventional drilling.

If you want to MAXXimise your machine tool productivity in 2016, please visit the OPEN MIND Stand 5965 for a full demo.