OPEN MIND Launches New Version of hyperMILL & hyperCAD at EMO

18 July 2013

At the forthcoming EMO show in Hanover, leading CAM developer OPEN MIND Technologies will be officially launching its new hyperMILL 2013 CAM package that offers a number of new, powerful features, extensive functional upgrades and greater ease of use. On Stand K16 in Hall 25, the most significant advance comes in the shape of the new 'hyperCAD-S®' CAD core, which is optimally matched to the hyperMILL CAM solution.

The 2013 version of hyperMILL has a multitude of new features throughout many of its established strategies. The millTURN feature that is of increasing importance in the rise of the multi-functional mill/turn centres now incorporates full machine simulation and collision checking of rotational chucks and clamps. It also includes a hard machining feature for inconel, titanium and additionally difficult to process materials that require variable in-feeds and automatic ramping. Support of the steady rest and tailstock with automatic and manual positioning and individual cutting parameters for contours has also been included to the millTURN package.

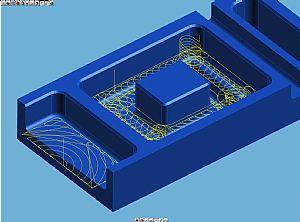

With regard to hyperMILL’s 2.5D and Macro element, the developers at OPEN MIND have created a new minimal distance parameter for holes, plus a generic pocket feature for ‘pockets’ equivalent to the ‘generic hole’. Further additions include a 2D contouring feature that enhances compensation and tolerance checking. This 2.5D enhancement has also been extended to incorporate hyperMILL’s roughing strategy hyperMAXX with a pocket milling addition to the 2.5D feature.

The 3D strategies for more complex machining have also been improved in hyperMILL 2013, with enhancements including a 3D arbitrary stock roughing cycle for better checking of conical tools. This has also been extended to hyperMAXX, providing multiple allowances for feed rate control, entry and plunging into pockets. Another addition is the 3D rib machining cycle that provides slot recognition for conical tools with full collision avoidance.

For full 5-axis machining, hyperMILL 2013 really does open up a realm of new possibilities. For 5-axis drilling, softer machine movements with high speed connections for time saving have been incorporated. Furthermore, OPEN MIND has developed 5-axis linking checks to monitor the collision situation of ‘connection movements’ against the actual stock. To support the increasing use of barrel cutters, the 5-axis Form-Offset-Finishing cycle has been created. This works efficiently with barrel cutters, conventional milling and spiral step-down processes. Another addition to the 5-axis platform is the 5-axis impeller feature that provides a smooth connection and path extension for rough and finish machining of impellers. This drastically cuts programming and cycle times whilst improving surface finishes on these complex forms.

Commenting upon the arrival of the new hyperMILL 2013 package, Adrian Smith, the Managing Director at OPEN MIND Technologies UK comments: “The arrival of hyperMILL 2013 is an extremely exciting period for us. The developers have improved every cycle from 2D machining right through to the most complex 5-axis machining strategies. Whilst improving the cycles, OPEN MIND has consciously worked hard to further improve the user friendliness of what is already perceived to be the most user friendly and comprehensive CAM package on the market. The new features to improve programming and cycle times, whilst making the package ever more intuitive and friendly for the end user is a credit to the developers at OPEN MIND. We will be hosting a series of user events over the coming months and will look forward to demonstrating the benefits of hyperMILL 2013.”

The current version contains new system components and significant upgrades, which provide users with new opportunities to more effectively and reliably create NC programs and increase manufacturing productivity in the process. With regard to hyperCAD-S, it is a brand new modern CAD system, with the architecture, core, graphics, database, user interface and API all being new software designs.

The CAD solution is highly adapted for CAM-specific tasks and has been tailored to meet the special needs of NC programmers. The newly-developed hyperCAD-S core is perfect for imported data. Users have the advantage of being able to easily modify any of the geometry elements at any time.

Curves and free-form surfaces are depicted using Bezier and NURBS geometries. In addition to the familiar basic elements for construction, the core now also provides a number of elements that specifically aid CAM programmers, including tool paths, polygon networks, point clouds and a rectangular element were all added to the core. For further information, please contact your local OPEN MIND representative or come and visit us on Stand K16 in Hall 25 at EMO in September.