OPEN MIND To Show F1 Industry's Benchmark CAM Package at Autosport

27 December 2014

At the Autosport International 2015 exhibition from the 8-11th January OPEN MIND Technologies will be demonstrating why it is the Motorsport's leading CAM provider. Currently working with 8 of the 11 F1 teams and claiming to have parts manufactured with its hyperMILL CAM package in 100% of the F1 starting grid; OPEN MIND will be demonstrating why it has a dominant position in the F1 market at the event.

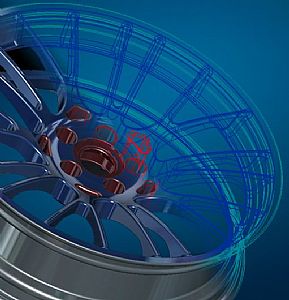

On Stand E1071 OPEN MIND will be highlighting its hyperMILL and hyperCAD-S packages that have been selected by the worlds' leading automotive engineers. The CAM vendor has undergone endless feasibility tests, demonstrations and presentations to prove its suitability and benefits over its CAM competitors. OPEN MIND has proved its value with the leading racing teams; with the engine manufacturers, chassis builders and the subcontract community following suit - giving OPEN MIND its benchmark position.

With the established hyperMILL CAM package enjoying a dominant position in the industry, Autosport 2015 will be an opportunity to promote the latest version of its hyperCAD®-S CAD suite and the new features within the CAD package that has been developed specifically for CAM users. In hyperCAD®-S, OPEN MIND has developed its own CAD system that is ideally matched to its CAM system hyperMILL®. This CAM-CAD software is specifically designed to address the requirements of NC programmers. hyperCAD®-S provides the hyperMILL® CAM system with a modern and highly user-friendly interface.

For visitors to Autosport, OPEN MIND will be demonstrating the new ‘Deformation’ module that gives the user the option to deform all geometries in accordance with requirements. This applies to both local and global component areas. What is the benefit for CAM programmers? OPEN MIND application engineer, Mr Ken Baldwin explains: “It’s quite simple. If warping occurs during the manufacture of thin-walled parts, it is extremely useful to be able to compensate for this beforehand by making a specific change to the geometry!”

For the motorsport community, the benefit is the ability to manufacture a part that meets the intended requirements. As an example, a turbine blade that may have warped 'a little' during production can be offset in the opposite direction before generating the program. This will result in an extremely accurate geometry after machining. With more thin walled components and complex geometries cropping up in F1, this will be a major benefit to the industry.

For the application of existing 2D lettering on to 3D geometries, OPEN MIND has created its volumetric deformation tool. In this process, selected elements such as surfaces, curves, points, point clouds and meshes are deformed volumetrically onto a target surface. There are no boundaries to user creativity, so why not visit the OPEN MIND Stand at Autosport and realise your potential.