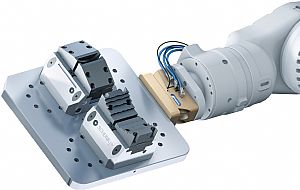

Powerful robot coupling for pallet handling

28 May 2012

If machine tools are loaded automatically, a reliable, precise and space saving workpiece change is playing an important role. For this particular case, SCHUNK, the competence leader for clamping technology and gripping systems has developed a slim, light-weight coupling with minimized interfering contours. This enables pallet loading to take place very close to the machine table. By using the VERO-S NSR, very thin attachments to the clamping station and pallet are feasible, and therefore a lot of space remains for the workpiece in the machine envelope for the movement of the axes.

At a weight of 1.6kg (size 160), the robot coupling achieves pull down forces of up to 15kN. The extremely rigid system transfers torque of up to 1600Nm, and is also suitable for reliable handling of heavy pallets of up 350kg with dimensions of 400 x 400mm. Every quick-change pallet system from the family owned company is equipped with a double angle clamping stroke that allows such large weights. In order to achieve an optimal relationship between rigidity, robustness and weight, the SCHUNK engineers have designed every part in aluminum that does not transmit force. The parts that do transmit force are produced from hardened stainless steel for additional strength.

The module locking system is 'self-locking' and uses form-fit clamping. At a pneumatic system pressure of 6bar, the module can be unlocked without requiring lubrified air. Opening and closing as well as pallet presence are monitored via inductive proximity switches. This enables the whole changing process to be monitored. Moreover, the module has a high compact performance that is completely sealed and thus protected against chips and coolant.