Precision Machining - Starrag presents new 5-axis Heckert X90 machine

3 October 2025

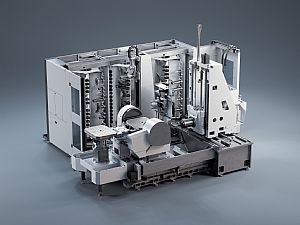

Starrag has launched the Heckert X90, the flagship of its versatile 5-axis machining centre range that delivers exceptional precision and productivity for large-scale manufacturing. Building on the acclaimed Heckert HEC series, the Heckert X90 features a workpiece-side swivel unit, allowing for high-dynamic 5-axis machining from a single clamping position with unparalleled capacity.

The Heckert X90's lightning-fast 65 m/min traverse rate and industry-leading tool changeover times enhance productivity for large components. Pallet changes are completed in just 22 seconds, whilst the tool changer provides chip-to-chip times of only 8.3 seconds. Standard 800 by 1000 mm pallets incorporate Starrag's precision-engineered concave surfaces with 6 µm curvature depth, ensuring stable positioning of the largest parts.

The Heckert X90 offers X, Y, and Z axis travel of 1750 by 1300 by 1400 mm while requiring 18 % less installation space than its HEC Series predecessor. It accommodates workpieces with a core contour diameter of 1400m and an extended workpiece contour diameter of 1.6 m, with a maximum height of 1 m, supporting loading masses of up to 2000 kg. With optional Y-axis stroke extensions of up to 1.4 m and Z-axis up to 1.8 m, the Heckert X90 provides maximum flexibility for oversized components. Within robust dimensions of 8.9m by 4.6 m, this machine delivers exceptional space utilisation without compromising performance.

The Heckert X90 provides a comprehensive range of spindle options that cater to specific application requirements, from the 12,500 rpm hollow shaft spindles to 15,000 rpm motor spindles, as well as various gear spindles that offer increased torque for heavy machining operations on large workpieces.

Starrag's innovative tool change system offers both lightweight and heavy-duty versions. The lightweight option accommodates tools weighing up to 22 kg, while the heavy-duty version supports tools weighing as much as 50 kg. The maximum tool dimensions are 800 mm in length and 325 mm in diameter, providing versatility for complex large-part machining.

Tool magazine options include timing belt magazines with 45 or 60 positions for HSK-100 tools, chain magazines accommodating up to 120 HSK-100 tools, and tower magazines supporting up to 450 HSK-100 tools, ensuring ample tool capacity for extended unmanned production runs.

Turning technology is integral to the machine concept and available as an option. Using specially developed assemblies and software modules, both standard and complex turning operations can be performed with machining centre productivity levels. Unlike turning centres, the machine benefits from versatile setup options, including vertical workpiece clamping and mid-operation clamping via the pallet changer.

For optimal operator experience, the Heckert X90 boasts Starrag's ergonomic 24-inch touchscreen HMI paired with a powerful Siemens SINUMERIK ONE control system. The touch-sensitive display responds to gloves and features a scratch-resistant, easy-to-clean surface. Operators can access PDF construction plans and sequence sketches while maintaining visibility in the workspace through an integrated camera. New hardware and rapid sensor technology enhance automation capabilities via extended 13-channel clamping hydraulics and optimised standard interfaces for pallet storage systems and robot cells.

Efficient chip management employs a thermo-symmetric design and steep-angled fixed plates, enhanced by an internal coolant supply operating at pressures of up to 80 bar. This setup ensures effective cooling and chip evacuation, with an additional flushing capability of up to 280 litres per minute for applications that generate a high volume of chips from large-scale machining operations.

The Heckert X90 integrates seamlessly with Starrag's comprehensive automation solutions, including round or linear storage systems, and robotic cells, catering to production requirements from small to large batch sizes. The extended work envelope makes it particularly suitable for automated production of large aerospace, energy sector, and heavy industrial components.

The new Heckert X90 utilises the proven four-axis Heckert H-series machine envelope. Instead of the NC rotary table from the H-series, X-series models feature a robust rotary/tilt table developed and manufactured in-house at Starrag's Chemnitz plant. The tilting unit incorporates two equally sized bearings and a thermally stable design, enabling five-sided, highly dynamic machining of complex large-scale components.

Ensuring pallet compatibility across the new Heckert X90, smaller X70 and X80, and larger variants was essential for developers. Pallets are interchangeable with Heckert H series machines and older Heckert HEC 630/800 X5 machines, providing investment protection and operational flexibility.

The Heckert X90 is now available as part of Starrag's expanded X-series line of 5-axis machining centres. The Heckert X-series includes the smaller Heckert X50, X70 and X80 variants, with the X90 offering the largest work envelope and capacity for the most demanding large-part manufacturing applications.