Rainford Breaks Boundaries for Drilling at Speed

25 November 2014

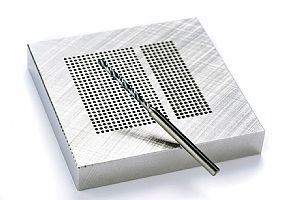

The new Iwata Tool 'Great Performance' (GP) Drill is probably one of the most understated product names in the industry. Now available from micro and hard machining specialist Rainford Precision, the GP Drill Series can drill at blistering feed rates that exceed 4m/min on a variety of hard materials.

Undoubtedly the benchmark in the next generation of drilling products, the GP Drill can drill anything from mild, carbon, alloy, and stainless steels through to ductile & cast irons, titanium and aluminium alloys to ceramics at astounding speed and feed rates. Thus making the micro line of drills the ideal solution for any machine shop processing small holes.

Manufactured from a microscopic carbide grain substrate, the GP Drill incorporates Iwata Tool's unique ALT coating that is ultra thin. This feature makes it ideal for resisting high levels of heat, wear and oxidation on the micro tools in the GP Series. The new high precision GP Drills are available in diameters from 0.3 to 1mm in 0.01 increments and from 1 to 3mm in 0.05 increments, delivering micro precision for all your small holemaking needs. The series is available with either the 5XD or 10XD flute lengths for high speed drilling to a depth of 36mm.

The unique drill point geometry is what delivers unrelenting performance levels and tool life with the understated GP Drill. Iwata Tool has developed a dual point angle drill with a 140 and 100 degree point. To the naked eye, this makes the drill point look like a ball nosed endmill. However, the reasoning behind the unique geometry development soon becomes apparent. The GP Series has drilled mild steel at a speed of 32,000rpm with a feed rate of 3.2m/min to process a 1mm diameter by 4mm deep hole in a lightening quick 0.25 seconds. The result was 1200 holes drilled in under 5 minutes with no pecking cycle.

With such astounding speeds and feeds, a rapid drill burn-out would be expected - no such chance. The GP Drill continued to process another 20,000 holes that totalled over 80metres of drilling at the 3.2m/min feed rate with no signs of excessive wear.