Rainford Has a Long Neck for Hard Machining

8 July 2015

Capable of machining hardened steels up to 70HRc, Rainford Precision has now extended the new range of HSB and HSLB ball nosed cutters from Union Tool. The HSB Series is a stub length tool with a short cutting length to improve rigidity and performance whilst the HSLB is a long series tool for machining difficult to reach surfaces and cavities with its 5XD reach.

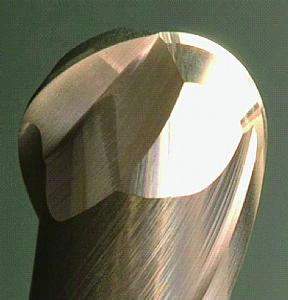

Machining materials in a hardness range beyond the comprehension of most cutting tool manufacturers, the HSB and HSLB two fluted end mills from Rainford Precision push the boundaries of hard machining. This is credit to the new Hard Max coating technology that is unique to the Japanese tooling manufacturer. The Hard Max coating improves oxidation resistance to improve productivity on a range of materials that include carbon, pre-hardened and alloy steels, hardened steels up to 70HRc, cast iron, copper, titanium and heat resistant steels.

The ability to machine a diverse range of materials up to 70HRc is permitted by the innovative geometry as well as the coating technology applied. The ball tip point has a super-negative rake angle that increases the thickness of the cutting edge to promote chipping resistance when dry or wet cutting of difficult materials. In addition, a negative rake angle on the cutting edge periphery further improves machining performance, chip flow and surface finishes by reducing vibration and deflection. This feature is particularly prominent on the longer HSLB range where the long reach characteristics have the potential to instigate vibration.

The HSB Series of ball nosed end mills are available in diameters from 0.6 to 12mm with the majority of tool radii targeted at diameters up to 2mm. With up to 70 tool designations available, Rainford can provide a variety of radii with a selection of cut lengths for each tool radius - all available off-the-shelf. The new HSB is available with a cut length from 0.06mm on its 0.03mm radius tool through to 22mm on its 6mm radius cutter with a selection of cutting lengths offered on each radii to deliver the optimal conditions for machining hard materials.

To increase rigidity and machining performance, the HSB is supplied with a shank diameter from 4 to 12mm with a short cut-length geometry that eliminates vibration and any harmonic effect when cutting difficult materials at high speeds. This cutting performance is further enhanced by an overall tool length from 50 to 110mm that eliminates vibration and creates stability under difficult machining applications.

For longer reach applications, the HSLB Series has been extended to offer diameters from 0.1mm to 6mm with ball nose radii of 0.05, 0.075, 0.1, 0.15, 0.2, 0.25, 0.3, 0.4, 0.5, 0.6, 0.7, 0.75, 0.8, 1, 1.25, 1.5, 1.75, 2, 2.5 and 3mm. The smallest 0.05mm radius tool provides a 0.08mm length of cut and an overall length of 45mm and this overall geometry is retained through to the largest 3mm radius tool with its 4.8mm length of cut and overall length up to 120mm. To ensure the most robust and resilient machining conditions, the HSLB has a number of flute lengths available and this is complemented by a shank taper angle of 16 degrees to minimise vibration. With 109 new tool dimensions added to the HSLB and 17 new additions to the HSB Series, Rainford Precision can cater for all your hard machining tasks.