Schunk Enhances Machining Performance With FLEX

17 April 2015

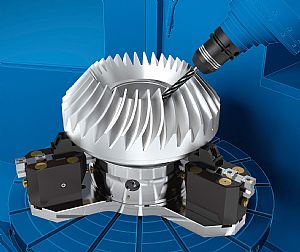

Regarded as the competence leader for clamping technology and gripping systems, SCHUNK has now developed the highly flexible manual chuck ROTA-S FLEX for manufacturers that want to machine a wide workpiece range on multi-purpose mill/turn machines. The new ROTA-S FLEX is an extension of the proven lathe chuck from the ROTA-S PLUS Series. The new ROTA-S FLEX has extended the guideways and this transforms the system into a large light line of chucks that are extremely versatile.

Compared to conventional lathe chucks used for large clamping diameters, the weight of the ROTA-S FLEX is reduced by 60%. At an identical table load, much heavier workpieces can be machined and due to the low working height, enough space remains for the workpiece and the cutting tools. Thereby extending the work envelope for the end user.

Simultaneously, for end users machining smaller workpieces, the extended guideways can be easily disassembled to improve workpiece accessibility when compared to a clamping application with conventional large chucks. A special lubrication system ensures the ROTA-S FLEX delivers permanently high clamping forces. Additionally, the new ROTA-S FLEX incorporates dirt seals that prevent chips and dust from entering the workpiece.

The ROTA-S FLEX can be easily assembled on a machine bed and by using the optimized jaw quick-change system, retrofitting can be completed within seconds. The ROTA-S FLEX chuck can clamp small parts as reliably as it can hold large parts whilst gauranteeing maximum operator’s safety. The clever clamping solution is available in the sizes 700, 1000, and 1200 for the ROTA-S plus, and the manual chuck ROTA-S plus 2.0 is available in sizes 315, 400, and 500. Depending on the size, the chuck (without top jaws) weighs 170kg, 360kg, or 490kg. The ROTA-S FLEX can be combined with numerous chuck jaws from the 1,200 types available from the world’s largest standard chuck jaw program from SCHUNK.