Schunk Launches Compact Quick-Change Modules

13 November 2012

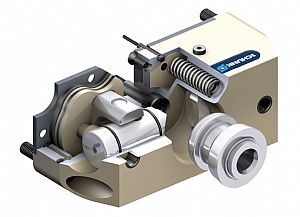

Small, confined spaces will always be an issue when using pallets and tools for automatic handling with a robot. For this type of applica-tion, SCHUNK has now developed the slim NSR-A quick-change module with optimized interfering contour that allows loading very close to the assembly or machine table.

Attachments that are very close to the clamping station and pallet are feasible. Furthermore, there is enough space for the components and the axis motion. For supplying the modules, handling and assembly tools, the module can be equipped with a SCHUNK standard media transfer for pneumatics, electrics or fluids.

At a dead weight of 1.6 kg (size 160), the NSR-A has a locking force of 14kN and therefore is an exceptionally rigid system. It is suitable for reliable handling of pallets up to 350kg with an overall area up to 400 x 400mm for the handling of tools. The SCHUNK locking system with the patented fast stroke and clamping stroke makes the handling of such an enormous amount of mass possible. The unit is form-fit and self-locking. Unlocking could be done with oil-free air as a pneumatic system pressure of 3.5bar is adequate.

In order to achieve an optimum ratio between rigidity, robustness and weight, SCHUNK development engineers have used high-strength, hard-coated aluminum for parts outside the power flow. The parts in-side the power flow are made of hardened stainless steel. The high-performance module is completely sealed to protect from chips and coolant. The locking and unlocking process is controlled by magnet-ic switches whilst the pallet and tool presence is interrogated by inductive proximity switches. The repeat accuracy is specified as 0.02 mm.