Schunk Set to Grip Crowds at Northern Manufacturing 2015

15 July 2015

At the Northern Manufacturing 2015 exhibition in Manchester on stand A45, Schunk will once again be promoting its Synergy Concept alongside a number of new products that have been launched recently.

Many manufacturers have now recognized they can improve surface finishes and tool service lives by utilising the innovative TRIBOS system; and at Northern Manufacturing from the 30th September to the 1st of October, the latest interfaces will be on show. These new interfaces deliver a higher level of standardization for the precision tool holding systems for micro machining and are now available with the TRIBOS RM and TRIBOS MINI ranges.

The TRIBOS-Mini that has been designed for high-speed micro applications can now be integrated with a high-speed HSK-E 20 spindle interface. The clamping technology experts at SCHUNK believe this newly standardized interface is superior to many short taper interfaces due to its accuracy at high speeds. In addition, it needs much less space compared to the HSK-E 25 interface. SCHUNK has designed the robust TRIBOS-RM with an extended L1 dimension of 78mm especially for high-efficiency 5-axes machining.

In order to allow precision machining of hard-to-reach areas, the mount can also be combined with the standardized TRIBOS-SVL tool extension with adaptations for HSK-A 32, HSK-A 40, HSK-E 32 and HSK-E 40 interfaces. In addition, SCHUNK has expanded its range in such a way that many of the previous special solutions will now be included in the standard catalogue. For example, TRIBOS-Mini will be standardized with ø 1, 1.5, 2, 3, 4, 6mm and 1/8 inch. TRIBOS-RM with ø 3, 4, 6, 8, 10, 12mm and 1/8 inch. In addition to the HSK-A 25, -A 32, -A 40, -E 25, -E 32, -E 40 interfaces that are already available, both mounts will also be available for HSK-E 20, HSK-F 32 as well as for BT 30 and SK 30. These units from SCHUNK are part of the world’s most comprehensive programs for high-precision tool clamping and can now be manually actuated via the SVP Mini and SVP-RM devices.

Additionally, Schunk will be keen to promote to the aerospace and composite machining fraternity the TENDO E Compact hydraulic expansion toolholder. Capable of reducing set-up times by up to 60% whilst generating up to 2000Nm of torque, the TENDO E Compact delivers micron precision for a host of machining applications. With this precision toolholder, even demanding applications with tight tolerances on the form, position and surface finish can be rapidly and reliably machined.

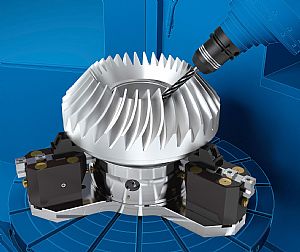

Another product that will be of interest to the high-tech visitors and exhibitors alike at the show, will be the innovative SPM Plus 138 fixture membrane. Manufactured from aluminum, the SPM Plus provides the clamping of a multitude of geometries from all sides with its innovative pull-down effect. Firstly, a 0.5mm high tuning ring is inserted between the quick-change pallet module and the fixture membrane, and then the exact workpiece geometry is milled according to the blank on the fixture’s clamping surface. Once prepared and the tuning ring removed, the workpieces can be inserted within seconds and the complete circumference be clamped by locking the VERO-S module. This in turn deforms the fixture membrane to provide the clamping.

Since the whole process is carried out within the elastic range of aluminum, the clamping operation can be repeated several thousand times. In contrast to conventional clamping blocks, the clamping force of this clamping method is carried out at the circumference of the whole workpiece contour and not just along an axis. Due to the clamping depth of only a few millimeters, the workpiece is fully accessible from five sides.