Schunk Shows Full Line-Up at Advanced Manufacturing Show

24 April 2015

At the Advanced Manufacturing Show that will take place at the Birmingham NEC from 2-4th June 2015, Schunk, the competence leader for workholding, toolholding and automation solutions will be demonstrating a range of products to cater for each of these disciplines.

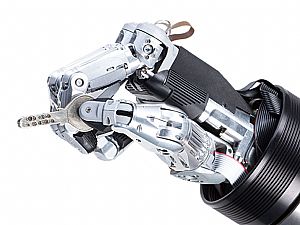

Making its UK exhibition debut will be the Schunk SVH servo-electric 5-finger gripping hand that will be complete with the Schunk lightweight arm, the LWA that will be controlled with a tablet via a Wi-Fi connection. The innovative new hand will be introduced at the show to support the rapidly growing automation demands of the UK manufacturing sector. Replicating the movements and characteristics of the human hand with its four fingers and a thumb configuration, the SVH has total of nine drives that permits various gripping operations to be executed with high sensitivity.

With its elastic gripping surfaces the new SVH ensures a reliable and strong gripping force on objects that enables it to be used for a multitude of tasks. In addition to new dimensions in gripping and manipulation tasks, SCHUNK is defining the possibility of the human/robot communication configuration by permitting gestures with the 5-finger hand.

From its comprehensive tool holding stable, Schunk will be showing a number of toolholding systems on Stand A404 to highlight the diversity of the product line. The renowned TENDO-E compact toolholding system that is available with the choice of an HSK-A 63, SK40 or BT40 back-end to accommodate tool shank diameters up to 20mm will undoubtedly attract show visitors. The vibration damping characteristics makes machining operations extremely quiet whilst improving surface finishes and runout accuracy. With an application range that caters for everything from rough milling to finish machining through to operations such as boring, drilling, reaming and thread cutting, the TENDO-E compact can achieve tool cost savings of up to 40% by achieving a permanent run-out and repeat accuracy of less than 0.003mm at 2.5XD.

Alongside this, will be the highly regarded Tribos system. The Tribos range ensures maximum tool life, even in the most difficult environments whilst minimising maintenance costs. Built for high-speed cutting at up to 60,000rpm, the Tribos has high radial rigidity and excellent vibration dampening to provide astounding machining results.

From the workholding stable, Schunk will be presenting examples of its Vero-S range. The Vero-S NSE Mini is acknowledged as the most flat pneumatic Quick-Change Pallet Module in the world, this new module provides ideal conditions for retrofitting existing machines, giving the end user full use of the work envelope to allow the direct clamping of small workpieces. Further highlighting the credentials of the Schunk workholding line-up will be the KONTEC KSC centric clamping vise. With the widest range of clamping set-ups with a single vise, the KSC is a multi-talented component of the stationary clamping systems. For conventional clamping, short clamping depths for 5-sided machining, mould parts, plates or saw cuts, the KSC can easily be adapted with the turn of a hand.

For the clamping of turned parts, Schunk will be demonstrating its market leading ROTA-S PLUS line of lathe chucks. The manual chucks with a quick-change jaw system ensures optimum results in workpiece clamping, especially on cycle controlled lathes. The new ROTA-S Plus incorporates an optimized wedge bar drive system and an improved lubricant system to ensure consistently high clamping forces. Since higher rotational speeds and cutting speeds are possible, users can apply more efficient cutting strategies that shorten the manufacturing time. The quick-change jaw system has an optimised drive that allows fast, comfortable and repeat accurate jaw changes. The innovative manual chuck is available in sizes 165, 200, 250, 315, 400, 500, 630, 800 and 1000mm.

With automation increasingly commonplace within industry, Schunk is well positioned to serve the manufacturing sector with its vast array of automation solutions. At Advanced Manufacturing, Schunk will be demonstrating the capabilities of its MGP-plus, the most proven gripper on the market. It combines an oval piston drive with roller guides, guaranteeing a high level of efficiency. This makes the 2-finger gripper ideal for small components with the most compact performance on the market. Due to the high force and payload characteristics, longer gripper fingers and higher gripping forces are possible with the same gripper size.

A wide selection of additional products will be available at the show for visitors to investigate and Schunk will have a team of work-holding, tool holding and automation experts on-hand to answer any questions that show attendees may have.