Sharpening Solid Carbide Tools at GrindTec 2014

7 February 2014

Sharpening diamond-tipped or solid carbide rotary tools will be the focal point of Vollmer's display at the forthcoming GrindTec 2014 trade fair, on Stand 1017. The Swabian leader in grinding and erosion machine technology will be causing a stir at the show with its new VGrind 160 grinding centre - the company's first grinding centre for processing carbide rotary tools.

Demonstrating its innovative machinery and services on an exhibition stand covering over 550 square metres in hall 1, Vollmer will be exhibiting under the slogan "Opening new paths to precision". The trade fair highlights for Vollmer will include the new VGrind 160 tool grinding machine and the QXD 250 erosion machine with new ExLevel Pro software. Additionally, Loroch, a Vollmer Group company will also be presenting its product portfolio in hall 1, at stand 1034.

"When manufacturing rotary tools, whether these are diamond-tipped or solid carbide, the sharpening process plays the lead role. The reason is that it determines the tool's level of precision as well as its service life. For tool manufacturers and their customers, it is the definitive mark of quality," says Dr Stefan Brand, Managing Director of the Vollmer Group.

Vollmer will be focussing heavily on the sharpening of solid-carbide and PCD tools at GrindTec 2014, the international trade fair for grinding technology, which is held in Augsburg, Germany, between 19th and 22nd March 2014.

The technology company and service provider will present seven of its current sharpening machines for tool machining, as well as a comprehensive range of services, covering everything from consultation, advice and training, to financing, maintenance and repair.

Grinding solid carbide tools and circular saws

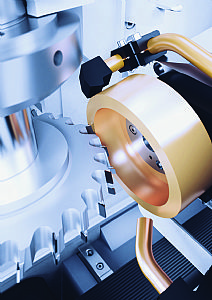

For Vollmer, the highlight will be the new VGrind 160 that can be used to manufacture solid carbide tools, by virtue of its kinematics and five optimally configured CNC axes. This enables it to deliver perfect interpolation with short travel distances in order to achieve maximum precision in the shortest time.

Several machines for machining circular saws will also be available at the Vollmer stand for visitors to examine. The CL 200 sharpening machine for the complete machining of carbide-tipped circular saws and the CNC-controlled CP 200 for sharpening hook and clearance surfaces will appear alongside the variant CPF200 for sharpening the sides. Additionally, the CHD 270 with eight CNC-controlled axes is on show for fully automated machining of circular saw blades.

Eroding diamond tools with a disc or wire

From their range of erosion technology, Vollmer will be exhibiting the QXD 250 erosion machine for machining PCD-tipped (polycrystalline diamond) rotary tools. The QXD 250 will allow tool manufacturers to machine 30% more PCD cutting edges than before, in the same amount of time. With its ability to generate single erosion pulses at a time, the new VPulse EDM technology allows surface quality to be increased by a factor of two or more. The extended travel distance and swivelling range of the machine means that tools with a diameter of 320mm and a length of 250mm can be accommodated.

Loroch has its own stand at GrindTec

Vollmer subsidiary Loroch, which is based in Mörlenbach, will also be represented at GrindTec 2014. On its stand 1034 in hall 1, Loroch will present its portfolio of automatic saw blade sharpening machines, including the new CNBS 100 automatic band saw blade sharpening machine. This is an upgrade of the CNBS 80. Another innovation from Loroch is the CNC-controlled PowerStar 850 sharpening machine which bridges the gap between the entry-level EKOSTAR 760 and the K850, a fully automatic saw blade sharpening machine solution.