SYIL UK Showcase Next-Generation Machines and Tools at Southern Manufacturing

19 December 2025

SYIL CNC UK Ltd will present an impressive line-up of high-performance machining centres and automation technology at Southern Manufacturing 2025, taking place at the Farnborough International Exhibition Centre. Exhibiting on stand E185, the company will demonstrate four machines from its expanding portfolio, all featuring cutting tools from partner TaeguTec UK Ltd.

At the heart of SYIL's exhibition will be the unveiling of the redesigned X5 and X7 VMCs, representing a significant evolution in the company's VMC range. The new designs prioritise ergonomics and aesthetics whilst maintaining the robust engineering that has established SYIL's reputation for delivering unparalleled quality at competitive price points. Key improvements include enhanced door operation, optimised swarf removal systems, an upgraded 12-inch Siemens control system, and improved visibility.

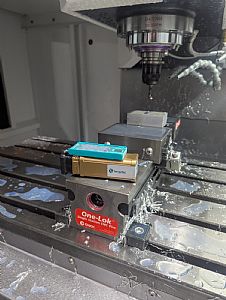

Visitors to the stand will witness live cutting demonstrations on both the X5 and the larger X9 machining centre. The X5 and X9 will showcase TaeguTec's latest high-feed milling technology, including the Chase4Feed line with its versatile four-corner BLMP inserts designed specifically for high-feed operations. The Chase4Feed's robust circular insert geometry enables exceptional performance in facing, shouldering, ramping and cavity machining applications, delivering depths of cut up to 2mm whilst maintaining excellent surface finish. Complementing this will be TaeguTec's innovative WINMILL series, featuring advanced small carbide inserts with V-shaped pocket designs that provide superior clamping strength and stability in compact diameter cutters.

TaeguTec’s WINMILL line incorporates an enhanced cutting edge design and high rake angle that significantly reduces cutting loads whilst improving chip evacuation, making it ideal for the precision shoulder milling applications. Additionally, the latest solid carbide TEO and TED drilling line from TaeguTec will feature prominently, showcasing advanced drilling performance.

A major attraction on stand E185 will be the X7 VMC equipped with SYIL's KUKA-powered robot loading system. The R1 tending system features a 16-station pick-and-play configuration that enables fully automated part handling.

Completing SYIL's display will be the L2 turning centre, a two-axis CNC lathe featuring a bar feed system and 12-station turret. This machine will be comprehensively equipped with TaeguTec's latest turning technology. The L2 will demonstrate TaeguTec's WINCUT triangular parting-off blade system, which features ultra-rigid SFTB triangular blades that deliver exceptional stability in both high-feed and interrupted cutting conditions.

The WINCUT system's specialised three-area insert contact with bottom-stopper design provides significantly improved rigidity and repeatability compared to conventional self-grip parting tools, whilst the internal through-coolant channels direct high-pressure coolant directly to the cutting edge to extend tool life. The L2 will also feature TaeguTec's high-feed turning range, incorporating advanced insert geometries and chipbreaker designs optimised for productive roughing and precision finishing operations across steel, stainless steel and difficult-to-cut materials. The combination of robust machine construction, linear guides in all axes, and TaeguTec's cutting tool expertise ensures dynamic and accurate turning operations that will be demonstrated continuously throughout the exhibition.

The relationship with TaeguTec, South Korea's largest and most innovative cutting tool manufacturer, enables SYIL to offer customers proven tooling solutions optimised for their machines. TaeguTec's extensive range encompasses turning, milling, drilling, threading, and grooving applications, with products designed to deliver consistent performance across diverse materials and manufacturing sectors.

Tom Marshallsay from SYIL CNC UK Ltd, commented: "Southern Manufacturing provides the perfect platform to demonstrate our evolved machine designs alongside TaeguTec. The combination of SYIL's engineering excellence and TaeguTec's cutting tool technology delivers compelling productivity benefits that UK manufacturers can implement immediately. We're particularly excited to show visitors the new X5 and X7 designs, which represent a significant step forward in terms of operator experience and production efficiency."