TaeguTec Expands DIA-MILL Composite Geometries

12 August 2025

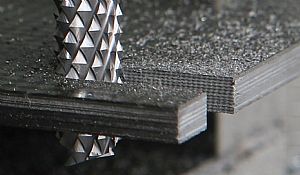

With the ever-increasing demand for cutting tools capable of delivering longevity and performance when machining composite materials, TaeguTec has announced significant enhancements to its DIA-MILL line. The upgrades include the arrival of the new RCME and RCDE geometries, along with the RDCF with a higher number of flutes to increase productivity and add versatility for the growing needs of manufacturers working with advanced composite materials.

The new geometries represent TaeguTec's response to the increasingly complex demands of the aerospace, automotive, and renewable energy industries, where composite materials have become essential due to their exceptional strength-to-weight ratios and durability. TaeguTec is said to be the world’s first carbide tooling manufacturer to have its own ‘in-house’ diamond coating chamber plant.

The RCME type features a multi-flute router design with a unique cutting edge shape optimised for medium to finishing applications. This geometry ensures excellent surface quality while minimising delamination, a common challenge when machining layered composite materials. Incorporating a high helix angle of 28 degrees, the RCME is available from 4 to 12mm diameter in 2mm increments with an overall length from 50 to 100mm and a flute length from 12 to 36mm depending upon the diameter selected.

Perhaps most innovative is the RCDE type, which combines the RCME cutting edge with an additional drilling cutting edge. This dual-purpose design enables drilling and slotting operations with a single end mill, reducing tool changes and improving production efficiency for medium to finishing applications. Available in the same dimensions as the RCME series, the RCDE is perfect for drilling, slotting and shoulder milling challenging composite materials.

For manufacturers requiring a superior surface finish, the enhanced RDCF series now offers increased flute options, with 6 or 8 flutes available. This increases cutting parameters while improving surface finish and overall performance compared to the current 4-flute variants that are also available in this series. The RDCF geometry features a low helix angle and a straight cutting edge specifically engineered to eliminate delamination and splintering – a common challenge for manufacturers in the field of CFRP and GFRP machining.

The expanded DIA-MILL line continues to include the established RRFE splitter range for roughing applications, which delivers low cutting forces and reduced vibration for high-productivity machining. Similarly, the RCFE multi-flute router excels in roughing operations by minimising cutting forces and vibration.

For applications requiring the elimination of delamination and splintering during finishing operations, the RCOM type, with its unique left- and right-hand helix design (up- and down-cut geometry), remains a standout option in the DIA-MILL lineup.

All product expansions are made with TaeguTec's premium TTD610 grade that ensures unrivalled performance and extended tool life even when machining extremely abrasive composite materials.

The expanded DIA-MILL line is particularly effective when machining carbon fiber-reinforced polymers (CFRP), glass fiber-reinforced polymers (GFRP), and honeycomb structures. For CFRP applications, the enhanced ranges operate efficiently at cutting speeds ranging from 50 to 300m/min, depending on the specific geometry and operation. The RCDE type, which combines drilling and milling capabilities, performs drilling operations in CFRP at cutting speeds of 50 to 150m/min with feeds varying based on diameter.