TaeguTec Takes Deep Machining Performance Further

1 February 2026

TaeguTec has expanded its renowned RHINO-TURN series of turning tools with the arrival of the new DNGX-ST insert. The remarkable DNGX-ST insert is a new 4-corner negative insert that represents a quantum leap forward in heavy-duty depth-of-cut turning technology. This exciting new addition to the TaeguTec turning stable will deliver unprecedented performance enhancements that can transform productivity for Swiss-type turning operations.

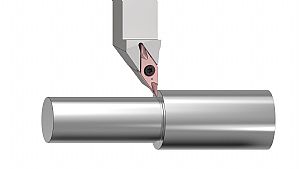

The phenomenal DNGX-ST insert showcases TaeguTec's exceptional chip breaker design that permits turning operations to a depth of 5mm – remarkably deep for the small turned parts industry. This dramatically reduces the number of required machining passes, resulting in spectacular productivity gains. The insert's ingenious 30-degree high rake angle design generates remarkably low cutting forces, ensuring superb surface finishes and outstanding tool life performance.

Furthermore, the DNGX-ST inserts demonstrate remarkably smooth chip control capabilities across various cutting conditions, ensuring continuous chip formation even when turning to maximum depth parameters. The advanced continuous chip formation minimises cutting forces, making it ideally suited for demanding Swiss-type turning centres, especially the latest sliding heads with servo oscillation swarf-breaking functionality.

Designed to be compatible with TaeguTec's RHINO turning holders, the impressive DNGX-ST ensures seamless integration into existing inventory without requiring costly additional investments. Available in both micro-honed edge and sharp edge configurations, the DNGX-ST accommodates a wide range of applications from precision finishing to aggressive rough turning.

The insert's four-corner, double-sided design offers an exceptional value proposition, providing more edges per insert than previous variants with two or three edges. The sophisticated DNGX-ST series also includes various corner radius options, ranging from 0.1 to 0.4mm, accommodating applications requiring intricate sharp-edged turning as well as catering for robust machining applications with its depth of cut range from 0.3 to 5mm. Feed rate capabilities span from 0.03 to 0.12mm per/rev, delivering significant flexibility for diverse machining needs across carbon, alloy and stainless steels.

TaeguTec offers the exceptional DNGX-ST insert across a range of advanced coating technologies, with the PVD-coated TT9020 and TT4430 grades available. For detailed technical specifications, expert application guidance, or prompt ordering information, contact your local TaeguTec representative or visit www.taegutec.com.