The Micro Machine of the Future

22 November 2014

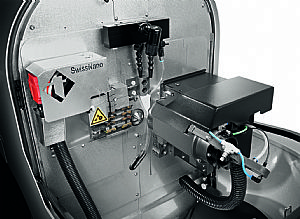

The watchmaking and micro machining industries are two sectors where Tornos has a well established reputation with regard to bar turning. Until the launch of the Swiss Nano, never has a manufacturer gone so far ahead in design, ergonomics and integration research with regard to a human-machine interface. Now, Tornos UK has a SwissNano at its Coalville headquarters for micro manufacturing companies to view the potential of this machine first hand.

Nobody knows the watchmaking sector better than Tornos and now, the company engineers have pulled out all the stops to develop a machine whose design stands out resolutely against other products in the market with the aim of creating a new machine tool category.

Combining all aspects of design

It is well known that design must bring together two aspects. Firstly, the aesthetics that play on emotional effect, and secondly the practical aspects that work on both a rational and emotional level. The Tornos Marketing Manager, Mr Brice Renggli says: "We wanted to create a modern automatic turning machine with a 4mm capacity, occupying minimum floor space and with complete 180° access. So, we have created a frontal design and integrated a tablet in addition to the conventional control."

Given the space constraints in watchmaking and small workshops, the Swiss Nano was developed so it doesn't require any rear access. If necessary, it can even be placed against a wall. The machining area is accessible from all sides.

The Swiss Nano was intended to be a resolutely, uncompromising watchmaking machine and its kinematics enable it to produce 75% of the moving parts in a watch. However, in the UK, Tornos envisages this machine making a significant impact in the production of small connectors and the electronic industry. Production for the watchmaking and electronics sector includes anything from simple to complex parts that may require gear hobbing.

With a footprint of 1.8 X 0.65 X 1.6m (LxWxH) and a maximum workpiece diameter of 4mm, the Swiss Nano incorporates an X1/Y1 tooling platten with seven turning tools with maximum shank dimensions of 8 X 8mm. The Swiss Nano also has the capacity for three end mounted tools with a diameter up to 16mm as well as another two end mounted tools for counter-operations. To meet the specific needs of the end user the Swiss Nano is available with optional extras such as a gear hobbing device, transverse drilling, HF spindles and polygon tools.

The 1kW induction motorised spindle and counter spindle are both capable of a maximum speed of 16,000rpm. Furthermore the Swiss Nano offers fixed, rotating and guide-bushless operation to ensure the customer receives the machine capable of producing all their parts in this diameter range. The Swiss Nano also offers peripheral additions such as a carousel collection system, vacuum, smoke extractor and fire prevention system.

The Swiss Nano includes a precision tool setting system using a sensor and feeler probe. The aim of this is to provide a user-friendly system able to position the tools to within 3 to 8µ, according to the bar diameter. The greatest advance may be in terms of communication. The Swiss Nano has a graphic tablet on top. All the basic production data (workpieces, products, machine, bar changeover, fleet monitoring) are reported on this interface. At a glance, the operator can access all the data for a specific machine or for a whole fleet of machines.