The Workshop of Tomorrow Available Today With Tornos

23 October 2013

At EMO 2013 Tornos unveiled its new programming software for its machines that will enable them to operate without assistance from the renowned TB-DECO system. Already in use by those who bought the first SwissNano machines, the new ISIS software is much more than just an ISO editor with a pleasing design. It also enables direct communication with machines and allows their status to be monitored.

Highlighting the benefits of ISIS, Mr Patrick Neuenschwander, software development manager at Tornos says: "ISIS is a programming system intended for machines controlled via an ISO editor, in particular SwissNano and Swiss ST 26 machines. It differs from TB-DECO, which is a horizontal editor. This editor, which can manage up to 3 channels, can display the ISO code vertically. The ISO code is automatically synchronised between the channels, and syntax highlighting is used to ensure easy identification of the various value codes.

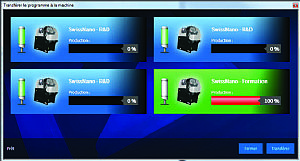

Identifying that ISIS isn't just a piece of programming software, Mr Patrick Neuenschwander continues: "Firstly, ISIS will be associated with the 'communication pack' option, which means it will be programming software and an industrial computer that can be added to the machine's numerical control to communicate with it via an Ethernet port. ISIS is much more than just a piece of programming software. It allows you to really communicate with your machine and transfer machining programs virtually via a LAN network. The computer built into the machine will open up brand new horizons hitherto unexplored in our industry. An example of this is the Tornos Android application, which enables changes to the machine inventory to be monitored in the same way as ISIS."

Highlighting the benefits of ISIS compared to other ISO editors, Mr Neuenschwander says: "One simple and very significant advantage is synchronisation error monitoring. Errors are displayed very clearly by a red icon on the screen, which prevents unnecessary journeys to and from the machine. However, the main advantage is management of the machine tool catalogue; none of our competitors' systems offer this. Not only is it possible to monitor the machine inventory, but you can also transfer programs from your computer directly onto the computer built into the machine."

"The program created with ISIS can then be integrated in the numerical control, tested and if necessary, corrected on the numerical control, and the corrections can be integrated in the desktop computer. Everything is fully compatible! ISIS also integrates workpiece information such as diameter, material, date and workpiece length. It also allows the usual documents to be printed, such as ISO code, workpiece information and tool catalogues. Another advantage of ISIS relates to its modern, highly flexible software structure. The interface is naturally multi-lingual, but so are the workpiece templates. It is now possible to programme a workpiece template in Chinese with a French interface, or vice versa.

When asked what the advantage of a tool catalogue is for the customer end user, Mr Neuenschwander continues: "For each machine, ISIS has a database that contains all of the tool resources, for example chisel holder plates, thread whirling tools, polygon tools or milling tools. Each of these tools has its own constraints and these are integrated in ISIS. So, if a tool is selected, only the positions where it can be fitted on the machine will be activated. ISIS also manages incompatibilities between the various tools. The user is guided intuitively through the use of his machine, and each tool has its own image to allow easy identification. Another advantage is that the default geometries are automatically displayed when a tool is selected. This means that when a cutting tool is selected, the standard tool geometries are directly incorporated. The user can easily access and change these in a table."

For technical reasons monitoring is only available on the latest FANUC CNCs on the new Tornos models. At present, the system is compatible with the EvoDECO 10, EvoDECO 16, EvoDECO 32, Swiss ST, MultiSwiss, Almac VA 1008, SwissNano, MultiAlpha and MultiSigma.

ISIS enables detailed monitoring of the machine inventory and monitoring can also be performed via the Tornos Android application, which was first integrated on the SwissNano. The functions are identical on both applications, but ISIS also offers advanced filtering options currently not available on the Android application. For example, machines can be filtered according to their status. Monitoring includes the status of the machines in the workshop and an overview of current production such as the workpiece counter, remaining production time and the name and drawing of the workpiece.

The new ISIS system is compatible with Windows XP, Vista and Windows 7 and 8. It requires the user to network the machines via a wired or WIFI network. The Tornos Remote Panel should be an Android 4.0 or later as the system is predominantly designed for 10-inch tablets.