Tool systems for interior boring and testing of ultra precise turned parts

6 May 2014

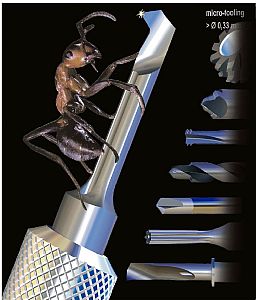

The miniaturization of turned parts, particularly when internal machining, demands completely new tool philosophies and concepts, as the 'scaling down' of proven tool geometries meets physical limiting factors. The effect on turning tools is magnified as they work with only one cutting edge and are loaded with axial, radial and lateral forces. The loads continually change when turning, with feed direction, depth of cut or interrupted machining all potentially taking place during a cycle. With the new line of Hobe cutting tools, Rainford Precision can now offer tooling solutions for the precision turning of micro components that take into account such physical properties.

For example, if you scaled a boring operation with a tool neck diameter of 3mm at a dressing depth of cut of 0.05mm and a feed of 0.025mm per tool revolution to a tool neck diameter of 0.3mm with a reduction ratio of 10:1, the cut values would be difficult to produce. The result would be a depth of cut 5Ám with a feed 2.5Ám per revolution at a speed of 80,000rpm instead of 8,000 rpm - something beyond the realms of most machine tools and tooling suppliers. Furthermore, the cutting edge radius would be 4Ám instead of 40Ám and the thickness of the hard material would be 0.15Á instead of 1.5Á.

As the resulting sizes cannot be produced unconditionally, it is necessary to look for other solutions. It is also unrealistic to produce a turning chip with a cross section of 2.5 Ám x 5 Ám because the cutting edge would be pushed away with these feed values and the tool would eventually break. Smaller cutting edge rounding, considerably less notching in the cutting edge area, optimized cutting edge and chip space geometries are needed at this point. These are required for giving the tool a better rigidity and for reducing the cutting force, as well as the passive forces with lateral effects. The vibration originated between the work piece and the boring tool will intensify in the tool neck and at the interface to the tool holder. The boring system 'borin«' from Hobe GmbH offers a perfect structure of the chain 'tool edge - tool neck - tool holder' and is readily available from micro machining specialist Rainford Precision.

As a micro machining specialist, it is only fitting that Rainford Precision has been selected as the UK distributor for such specialised products. The new tool system borin« has been developed for the rationalized boring of miniature bores. Its remarkable features are the small, precise dimensions in combination with the internal coolant feeding through its modular holder. The tool holder can be fitted directly on the machine or into standard clamping devices. The change of the hard metal insert in the holder is carried out by hand with simplicity.

The modular tools are suitable for bores from a diameter of 0.3mm. Given the precision of the modular tools and the special seating in the modular holder, a repeatability of ▒5Ám is guaranteed for the tool change. Therefore, a new measurement of the axial and radial position of the edge as well as the adjustment of the tip height after tool change can be eradicated.

Along with a standard range that comprises over a thousand tools in the diameter range of 0.4mm to 8mm, Hobe also supplies specially adapted tools to meet the demands of the customer.

The cutting geometries, chip removal flutes, internal coolant feeding and the coatings are adapted to the respective requirements. To achieve this, the customer needs only to supply a drawing indicating the material and the type of machine.

Complementing the borin« line, Rainford can also supply the new spinin« system from Hobe. For pre-machining, Rainford can offer spot drills with a web thickness of only 0.03mm. Pinpoint centring is absolutely necessary for drilling with very small tool diameters. Additionally, Rainford can also provide a modular system with a series of special tool types. The ě3mm, ě4mm and ě6mm modular shanks for the spinin« system are extremely straight and round.

Also on offer through Hobe is the exciting new tourin« line, derived from the French tourbilloner (whirling) and interne (internal), these tools are ideal for internal thread whirling and internal milling interpolation. In conjunction with Hobe, Rainford can offer a standard range for thread milling or whirling from size M1 up to size M4. With reverse chamfer or countersink tools starting from ě0.95mm. Working to such precision, the diameter and longitudinal position must be coordinated in a range of <0.01mm, tolerances that also apply to the flank angles and edge radiuses of the forming tools.

For testing these internal profiles, plug gauges are still frequently used. Hobe also has this covered with its probin« system. The micro probe tips can be seated in the borin« system if their admission shanks are identical with this system. The main applications for this rapid check system are ideal for internal shapes such as hexagon sockets, rounded teeth, threads, cylinders and also non-circular shapes.

However, as Rainford Precision re-iterates the use of such precision tools is always dependant upon the machine tools, the clamping tools and the control of thermal variables to guarantee the utmost in precision. As Rainford Precision's Managing Director, Mr Arthur Turner states: "To machine at such delicate parameters, customers cannot simply scale down their existing techniques. It is more often a case of adopting a whole new machining philosophy to achieve the desired results. At Rainford Precision, our expertise in the micro machining industry is second to none and to deliver the optimum results for customers. Our specialist team has extensive micro-manufacturing knowledge that is backed by the most comprehensive range of machine tool and cutting tool solutions for true 'micro manufacture'.