Tornos Celebrates Sales Success at Open House

17 October 2014

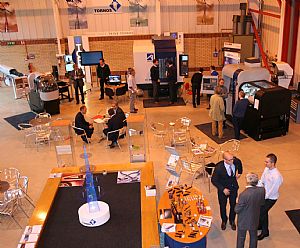

The recent THINK: Production 2014 event that was co-hosted by Tornos and Matsuura proved a resounding success for the Swiss sliding head lathe manufacturer. The three day event in Coalville, drew over 200 high calibre visitors with one of the Tornos highlights being the sale of an ST26 turning centre to Hullmatic.

The acquisition of the Tornos ST26 comes off the back of a successful ST26 installation in September. The first ST26 was installed at Hullmatic as a direct replacement for an ageing Deco 20 machine. Capable of balanced turning, milling and drilling, the ST26 can also provide material savings with its ability to run with/without a guide bush.

The order for a second ST26 is the result of Tornos expediting the process with a solution that was tailored to the needs of the end user. With a shop full of CNC sliding head technology from Tornos and CNC lathes from Mazak, Hullmatic is deeply imbued in the production of automotive components, boasting household names like Caterpillar, Dunlop, Perkins and Delphi as customers. Producing over 15 million parts each year, Essex based Hullmatic had been utilising their Tornos Deco machine for long production runs. However, the ability of the ST26 to maintain these long production runs whilst offering improved flexibility and reduced changeover times when compared to the ageing Deco was overwhelming. The immediate impact of the ST26 is why the company brought forward its plans for a second machine.

Commenting upon the purchase, Tornos UK's Head of Subsidiary, Mr John McBride comments: "The innovative tooling configuration on the ST26 enables Hullmatic to leave many fixed and live tooling stations set-up for a variety of jobs, drastically cutting job changeover times. Furthermore, the guidebush/bushless system can be changed over in 15 minutes compared to upward of 2 hours on alternate sliding head machines. These factors give a high quality and quantity manufacturer like Hullmatic the precision, capability and above all, the flexibility they need."

Whilst this acquisition was a highlight for Tornos, the event visitors were also drawn by the new CT20 and GT26 turning centres that arrived fresh from their world premiere at AMB. Tornos also gave its UK debut to the SwissNano turning centre that has been causing a stir in the micro manufacturing industry. Alongside these new innovations was the robust and powerful Almac CU3007 machining centre with a 5-axis Lehmann table set up. The new machines boasted a host of new technology and the extremely powerful 11kw spindles of the GT26 drew interest, but a clear crowd pleaser was the Tornos TISIS machine monitoring software. Linked to the CT20 and GT26 turning centres at the event, TISIS enabled the visitors to see the benefits of monitoring and programming one or many machines and their production status from one work terminal or mobile device.

To complement these leading products, Motorex, Delcam, Lehmann, Edgecam, Floyd Automatic, Rainford Precision, Arno Tooling, Baty and Iscar all demonstrated complimentary product ranging from cutting tools and workholding through to machine monitoring, finance and surface treatments.