Tornos Gives A Competitive Edge With New Machining Centres

12 June 2013

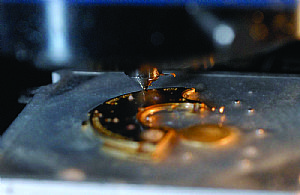

New linear guide rails developed by CNC machine-tool manufacturer Almac, ensure that Swiss watch-makers that use their ultra precise 3 to 5-axis machining centres produce better quality components. When this is coupled with the long-standing use of Alphacam, one of the most popular CAM systems in Switzerland’s watch industry; it’s easy to see why Almac are a leading supplier of high precision machines for all aspects of Swiss watch production as well as the production of intricate and highly precise components for a number of other market sectors.

Unique design

Almac Director Philippe Devanthéry says they are the only machine manufacturer using the technology of four linear guide rails fixed on a prism. Commenting: “This enables us to give a high warranty of movement in the Z-axis. The four guide rails hold the spindle in perfect linear position, so there’s absolutely no tilting of the spindle. Additionally, there’s no thermal displacement of the spindle, as the heat goes into the centre of the prism.”

He says the machines guarantee very high stability and accuracy and this gives top machining quality. “The watch-makers who use the Almac CU 1007 machining centres produce better quality components than their competitors that don’t have them. It has X and Y slides on pre-stressed rails and a ball screw. The vertical axis is formed by the solid cast iron prism, which a rectangular sleeve moves on. This is guided by the linear rails and moved by a ball screw. As well as the watch industry, Almac machines are used for other micro-machining applications such as medical equipment, aeronautics, jewellery and electronic component connectors, making them the ideal choice for the production of precision components."

A few microns

“Many of our customers, particularly leading names in the watch and high precision industries work to extremely accurate detail, often as tight as five microns. They need their machines to be in almost constant production day and night, so we supply the full package, including robots, loading and unloading stations and peripheral equipment for cleaning and deburring, all finely tuned to our customers’ needs” continues Mr Devanthéry. The company is located in La Chaux-de-Fonds at the heart of the watch industry and its employees know that their precision and orientation to quality, helps the Swiss watch industry shine worldwide.

Tailored solutions, both hardware…

In all cases where Almac produce components as part of the machine acceptance process, they use Alphacam to generate the NC codes. When handling new enquiries, it will receive details of a part for the manufacturing trials in a .step, .iges or .dxf file and create programs for the demonstration in Alphacam every time.

Almac also supply customers with special modules of Alphacam developed by the software’s Swiss reseller, MW Programmation, for a number of specialist functions. For instance, watch decorations were done by hand before Almac designed CNC machine tools to implement exclusive pioneering solutions for machining and decorating components that make up watch movements. These machines are programmed by Alphacam. Almac also produce a range of specialist machines for manufacturing dials, cases, case attachments and links.

Almac for today and tomorrow…

In order to ensure they remain a key machine supplier to the top end of the Swiss watch market and precision industries, Almac are developing the skills of a number of apprentices, to enable them to set the linear guide rails, which Philippe Devanthéry says is a specialised task. “It takes a high degree of expertise to manufacture our CNC machines, and an even higher degree of expertise to adjust the guide rails to the absolute level of precision required to ensure it is absolutely impossible to tilt the spindle.”

In conclusion, Mr Devanthéry explained: "Almac is entering a new period of development; we have a sound knowledge of our customers' business and our whole team is motivated to succeed. In addition, we can offer new solutions to complement our offering and meet a full range of needs. Don't hesitate to put your trust in an Almac solution; you won't be disappointed."

Close to customers

Almac is part of the Tornos Group, and has undergone restructuring in the past year. We asked Mr. Devanthéry to clarify Almac's situation: "There are now 22 of us at the La Chaux-de-Fonds site, and we have retained all of our expertise and activity in La Chaux-de-Fonds, for example marketing, sales, assembly, setup and fine tuning to meet customers' needs and services, to remain as close as possible to our customers". He added: "Being part of the Tornos Group is an advantage; for example, we can access resources that we may be lacking from time to time (particularly for assembly)".

The new director, appointed in November 2012, has visited numerous customers and, as he explains: "What's important for our customers is that Almac can offer long-term expertise and the customers can always count on us, and that's exactly what we're aiming for."