Tornos Keeps Watchmaker Ticking

The Swiss company DPRM based in Arch near Grenchen is located in the origins of the watch-making industry, crafting the most intricate parts for the most beautiful watches.

DPRM regards itself as a watch manufacturer that is mainly focused on the bar turning of micro parts that constitute the working features of a watch. The company also performs all peripheral activities in the fields of production, quality control and even assembly. To achieve sustained success, DPRM relies on Tornos and it's EvoDeco 10 and SwissNano machines for its in-house bar turning processes.

A renowned enterprise

Established in 1947 under the name ‘ASKA’, DPRM has been built upon a unique knowledge base that its employees have gained during the course of time. Using bar turning and gear cutting technologies, the company can develop and produce all kinds of components that meet the requirements of the high-end watch market. Today, DPRM is a part of the Dubois Dépraz Corporation, a famous manufacturer of exceptional watch components.

To manufacture its components, the benchmark in the watchmaking industry utilizes 44 machine tools. Besides the specialized machines for blanking, burnishing, decoration, thermal and surface treatment, the Swiss company employs seven EvoDeco machines, four Delta and one SwissNano from Tornos.

High degree of specialization

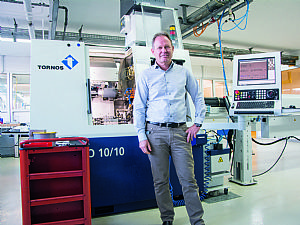

DPRM specialises in the production of arbours, pinions and wheels for high-end watches by means of gear cutting. Through its commitment to the luxury watch manufacturing industry, the company is used to meeting even the most demanding challenges. “Imagine any component that may be possible to produce from bar stock – you can rest assured that we are able to produce it, even if the production of the part does not involve turning operations,” Mr. Forster, Managing Director of DPRM, emphasizes.

“Our staff is used to success. We fully meet even the most complex demands. In any case, where we encounter problems, we work hand in hand with the customer to jointly find a solution. Our know-how is recognised by our customers throughout the industry and we are pleased to offer them our support as a co-developer for the industrialised production of even the most complex components,” Mr. Forster adds.

High demands

“Meeting tolerances in the range of 4 to 6 microns is part of our daily routine for almost all of our parts. Additionally, we have to consider the aesthetic aspects and high levels of surface finish. For instance, we can machine holes of Ø 0.3mm with a length of 7mm. That is a length more than 23 times diameter! On our EvoDeco 10, we can produce prismatic parts without any turning processes,”

Mr. Forster explains: “In addition to machining operations, the company offers highly complex assembly services. For instance, we produce and assemble cannon pinions (including friction spring adjustment), third wheels, counter wheels, reversing wheels, second wheels and much more.”

Unrivaled response

These days, responsiveness is the key to success. DPRM has fully understood these market forces. This is why the company has set-up a manufacturing cell for prototype production to respond quickly and efficiently to customer requests. “This unit was a great success and we have separated it deliberately from the production area to have a dedicated machine inventory, especially for such tasks. It was obvious from the very beginning which machines we should use for this cell. We installed two EvoDeco 10 machines. Compared to competing products in the market, these machines provide us with outstanding flexibility,” Mr. Forster adds.

The EvoDeco 10 machines enable DPRM to manufacture both simple and highly complex parts. Thanks to its fully modular machining area, the EvoDeco 10 can be converted to a milling center in no-time. Furthermore, these machines can be equipped with numerous high-frequency spindles. And, what’s more, the machines allow gear cutting in main and back machining operations.

EvoDeco: A first-class partner

“The EvoDeco machine is the first-choice solution for the production of our components. It is the ideal machine to meet the ever-growing demands on the complexity of the parts to be machined. If for large batches, a finish gear cutting process is the most appropriate option, this machine enables gear cutting without the risk of positioning errors. At the same time, the machine cuts down the tooling costs,” explains the company’s micro turning/CNC division manager.

“TB-Deco facilitates machine programming even when it comes to complex operations. The machine can be set up rapidly and the pre-setting device allows substantial time savings during machine set-up. The next process can be prepared while the current machining process is still active. The EvoDeco quickly reaches its operating temperature and boasts optimum thermal stability during the production process.”

“Thanks to the warm-up system, the machine is ready for production just when desired. The self-cleaning filter brings about considerable time advantages and the oil tank is large. The capacity of the chip bucket is better than on competitive machines. All in all, the EvoDeco machines deliver extremely easily maintenance processes. You can see that every detail has been conceived in a most intelligent manner with the operator in mind.”

SwissNano: High speed and precision

With its ergonomic features and its easy programming, the SwissNano also appealed to the DPRM team. “It’s amazing how easy it is to get familiar with this machine,” stresses the CNC division manager. He adds: “The machine is very precise and it works wonders in the production of small components where tight tolerances must be met. With its ability to machine usually less complex workpieces than with an EvoDeco machine, it perfectly matches our requirements and enables us to quickly respond to any type of request. The SwissNano can perform front machining and polygon cutting tasks to our complete satisfaction.”

High-quality service

“The product support offered by the Tornos Service team is excellent, just as is true for its responsiveness and professionalism. We know that we will always get the best solution for our problems from Tornos. Whether we have mechanical problems, problems with the software or simply with programming, we will get help from competent partners like Tornos. And, what’s more, excellent availability of any spare parts is guaranteed. On the whole, we are highly satisfied with the service Tornos offers for its products,” the Managing Director concludes.