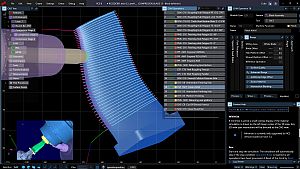

World premiere of RCS 8.0

11 November 2025

Starrag has now introduced its new RCS 8.0. This CAM software is used to machine turbine blades and now has learning capabilities. The world premiere at EMO 2025 demonstrated over 30 years of software experience, with the latest version of the software integrating pioneering functions such as automated workflows and precise geometrical adaptation to variable unmachined parts – a clear step forward for complex free-form contours.

‘Le mieux est l'ennemi du bien’ – Perfect is the enemy of good. The French philosopher Voltaire noted this over 300 years ago. He warned against destroying things that are already good in the pursuit of perfection. The skilled programmers in Rorschacherberg, Switzerland, have been heeding this warning for more than 30 years: Instead of rashly discarding the tried and tested, the teams at Starrag developed it further. The RCS systems for the high-precision machining of turbine blades and complex free-form surfaces have been produced there since 1984.

Proven use by long-standing aerospace customers

The CAM programs have proven remarkably successful on the Starrag LX series machines, where they are not simply an additional tool, but an integral part of the overall architecture. The early RCS versions 1 to 6 were mainly used in the 5-axis machining of aerospace components, and are still in productive use by numerous Starrag customers today. The subsequent 7 series brought advances such as best-fit workpiece alignment, automatic ‘dengeling’, collision avoidance and combined roughing/smoothing strategies.

Updates to RCS 7.8 brought numerous optimisations for practical use. These included an extended tool holder management system with over 100 tool holders, improved flank machining with a variable contact zone to extend tool life and Z-level roughing across complete blade geometries.

Another new feature was the ability to automatically adjust the feed rate in the material removal simulation, which was able to reduce the machining time by up to 20%. The function to automatically skip machining steps depending on the condition of the unmachined part provides greater flexibility. It is particularly useful for forged workpieces with irregular geometry. It is for these reasons that many users manufacture their turbine blades with this CAM software.

Backwards compatibility

However, users who switch to the latest version of the software will not have to go without these tried-and-tested functions and the features that were introduced in version 7.8. That's because the Starrag development team has once again kept Voltaire's warning in mind – and took the deliberate decision not to start from scratch, as it moved into the next generation. RCS 8.0 is characterised by comprehensive backwards compatibility with projects from RCS 7.x.

Existing NC strategies, program structures and milling paths can be transferred over and seamlessly integrated into the new form of AI-supported machining. The new version of the software, therefore, does not replace tried-and-tested cutting strategies, and they instead become part of a new AI strategy. Users benefit from familiar processes – enhanced by automated workflows, modern geometry algorithms and AI optimisation.

Optimal cutting with real-time feedback

The new RCS 8.0 software brings noticeable advances in user guidance, process control and feedback. A modernised user interface, intelligent navigation with integrated error analysis and asynchronous workflows enable continuous work without interruption. Compared to the previous version, RCS 8.0 provides more direct real-time feedback – and thus opens new opportunities for dynamic, process-oriented cutting on 5-axis machining centres.